Total Solutions from SK Global

- 2023-10-13

Here is the last day of the Mokkiten Japan 2023. We are very glad to have interview with Mr. Cliff Chang, CEO of SK Global from Taiwan, NewsWin : Hi, Mr. Chang , can you tell us about SK Global ‘s production features and service? Mr. Chang:Yes , of course .SK Global is a company specializing in the turkey project like automation of the Glued-laminated timer . In Japan I think the labor cost is higher. we have many customers they are looking into a total solution for integrating all kind of machine into the same line in order to produce the gluename and CLT. We are the company we have all the designing of the whole line and we have all the software program can provide total solution to all these Japanese customers. By NewsWin

Mokkiten Japan 2023 shows“Work that connects forests and people”

- 2023-10-10

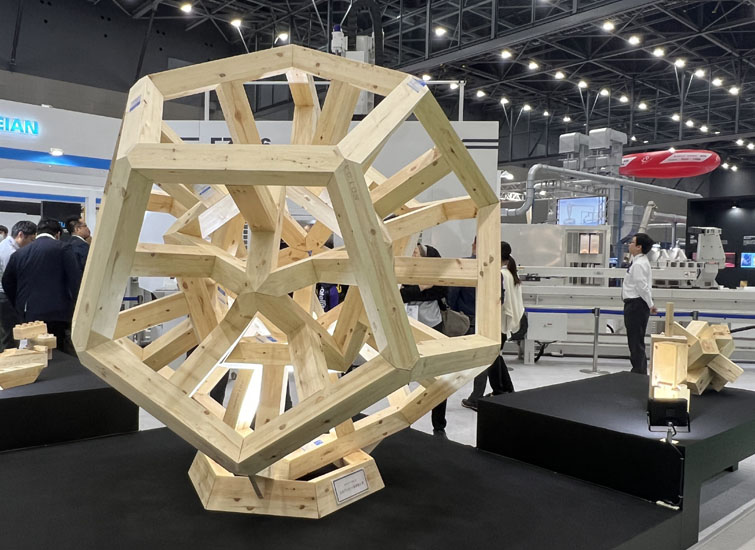

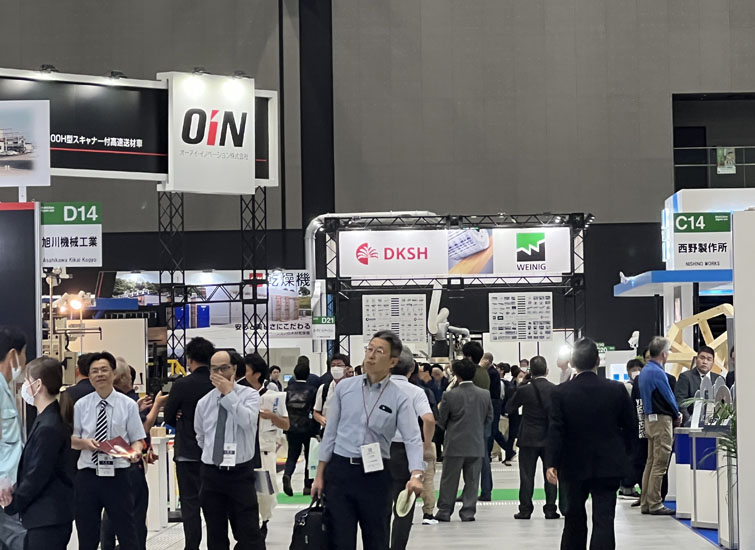

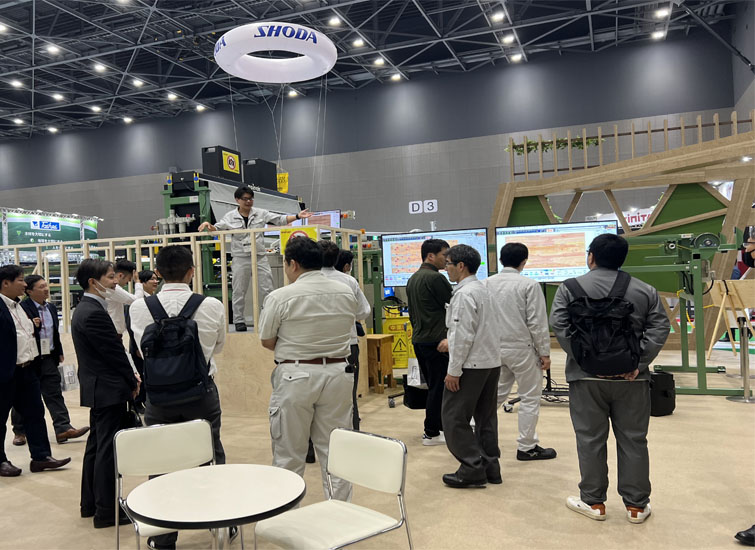

Mokkiten Japan grand opened on Oct 05,2023, This is the 46th as the largest general exhibition of wood machinery in Japan.

There were 155 companies and organizations exhibiting and 1,063 booths, making it one of the largest in the past 20 years.

This time, it was held at the newly established Port Messe Nagoya New Exhibition Hall No. 1. The New No. 1 Exhibition Hall is one of the largest in Japan, with approximately 20,000 square meters of pillarless space, and is directly connected to “Kinjofuto Station” on the Aonami Line, making it a very convenient exhibition venue for visitors.

The theme of this exhibition is “Work that connects forests and people”. Japan has abundant forest resources. It is our urgent task to use this renewable resource carefully. One of the answers is the utilization of wood by wood processing machines. A wood processing business that connects precious forest resources, which are the blessings of nature, to people’s lives. That wooden skyscrapers are being built one after another, the wood processing industry is needed to realize a sustainable society. Please see “Work that connects forests and people”.

In order to make this exhibition worthwhile for everyone, the organizer made it a big event where cutting-edge technologies and solutions that support our lives and create a prosperous future society, such as all technologies that utilize DX for the future of the wood industry, advanced image processing, AI, IoT, and robots that solve labor shortages, will come together. In addition to domestic manufacturers and sales companies, many overseas manufacturers will gather to provide visitors with a large amount of cutting-edge information on cutting tools, paints, adhesives, drying, dust collection, construction, furniture hardware, DIY, and related equipment, along with newly developed processing technologies such as lumber, plywood, laminated lumber, woodwork, pre-cutting, ceramic siding, and resin.

The exhibitors and machinery form Taiwan are Anderson group, Kuang Yung, Leadermac , CPT , SK Global , Joway ,CYWWM,BOARK, DING_CHANG tool, TAI CHUN,GAU JING, INNOVAOTR, CKM,YUAN AN, NewsWin Media etc.

The exhibitors and machinery form Taiwan are Anderson group, Kuang Yung, Leadermac , CPT , SK Global , Joway ,CYWWM,BOARK, DING_CHANG tool, TAI CHUN,GAU JING, INNOVAOTR, CKM,YUAN AN, NewsWin Media etc.

.jpg)

.jpg)

Biesse at VietnamWood 2023: Showcasing Biesse's new identity and technological solutions

- 2023-09-26

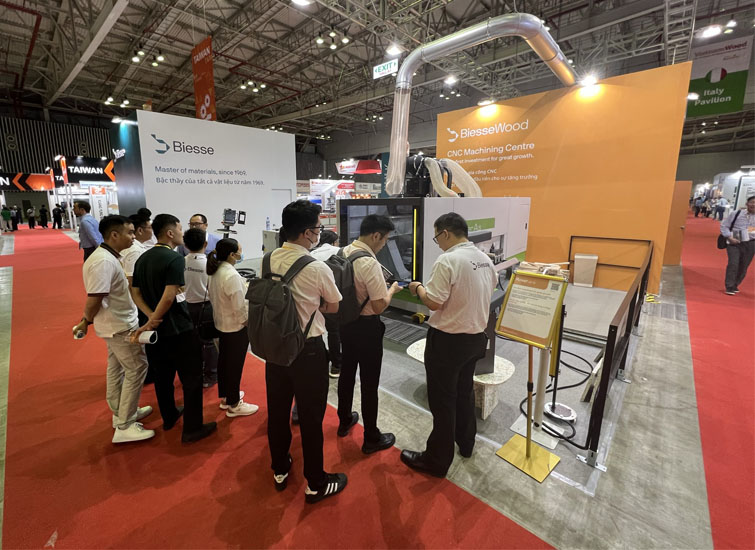

Ho Chi Minh City, 21 August 2023 – Biesse present at one of the most prominent woodworking exhibitions in the region, VietnamWood 2023, which took place in Ho Chi Minh City, Vietnam on 20 – 23 September 2023. This is Biesse’s comeback since its last participation in 2019 and present a whole new look that expresses the company’s evolution journey, along with two machines and software solutions.

“Biesse has always been at the forefront of technological advancements. VietnamWood 2023 provides an ideal platform for Biesse to demonstrate its commitment to excellence, innovation, and customer satisfaction. The exhibition witness the unveiling of Biesse's new brand identity, which reflects the company's evolution and growth while reaffirming its position as a trusted partner for woodworking professionals worldwide,” says Raphaël Prati, Chief Marketing & Communications Officer. At VietnamWood, physical and video elements will be applied to stimulate the visitor’s imagination and portray the company’s multi-materiality attribute. Five stations display the processes of material transformation, while multimedia elements show the results of the transformation, emphasising the potential of the processed materials themselves.

Besides the new refreshing visual and identity, Biesse also showcase the current technologies that are relevant to the Vietnamese market. Located in Hall A, Stand 060, the star attractions at Biesse's exhibition booth for two machines: Rover AS 15 and Opera 5. The Rover AS 15 is a versatile CNC machining center known for its precision and reliability. Equipped with advanced features and automation capabilities, the Rover AS 15 guarantees exceptional performance and flexibility in woodworking applications.

.jpg) The Opera 5, on the other hand, is a high-speed finishing and calibrating machine, designed to optimise productivity without compromising quality. This machine is ideal for large-scale production environments, offering speed, accuracy, and efficiency to meet the demands of modern woodworking businesses.

Biesse also showcase its software solutions. Visitors have the opportunity to explore imos, an innovative CAD/CAM software that enables seamless integration of design and production processes, maximizing efficiency and minimizing errors. The b_Solid software is on display, demonstrating its capabilities in 3D design and simulation, aiding in accurate visualisation and optimisation of woodworking projects. Additionally, Biesse's

SmartConnection software is highlighted, showcasing its ability to connect and streamline production processes for improved productivity.

Biesse team at VietnamWood 2023 consisted of industry experts who was available to engage with visitors, provide in-depth demonstrations of the showcased machines and software solutions, and offer personalised consultations to address specific woodworking needs.

"We are thrilled to participate in VietnamWood 2023 and present Biesse's innovations to the woodworking community in Vietnam," said Ettore Vichi, Chief Regional Officer EMEA and APAC. "With our new brand identity, cutting- edge machines, and advanced software solutions, we aim to empower woodworking professionals with the tools they need to achieve greater efficiency, accuracy, and profitability. We look forward to welcoming visitors to our booth and showcasing the future of woodworking technology."

VietnamWood consistently presents a valuable opportunity for industry professionals, woodworking enthusiasts, and decision-makers to witness Biesse's commitment to excellence and explore its latest offerings. Biesse invites all attendees to visit its booth at the exhibition and experience firsthand the innovative solutions that are shaping the woodworking industry.

The Opera 5, on the other hand, is a high-speed finishing and calibrating machine, designed to optimise productivity without compromising quality. This machine is ideal for large-scale production environments, offering speed, accuracy, and efficiency to meet the demands of modern woodworking businesses.

Biesse also showcase its software solutions. Visitors have the opportunity to explore imos, an innovative CAD/CAM software that enables seamless integration of design and production processes, maximizing efficiency and minimizing errors. The b_Solid software is on display, demonstrating its capabilities in 3D design and simulation, aiding in accurate visualisation and optimisation of woodworking projects. Additionally, Biesse's

SmartConnection software is highlighted, showcasing its ability to connect and streamline production processes for improved productivity.

Biesse team at VietnamWood 2023 consisted of industry experts who was available to engage with visitors, provide in-depth demonstrations of the showcased machines and software solutions, and offer personalised consultations to address specific woodworking needs.

"We are thrilled to participate in VietnamWood 2023 and present Biesse's innovations to the woodworking community in Vietnam," said Ettore Vichi, Chief Regional Officer EMEA and APAC. "With our new brand identity, cutting- edge machines, and advanced software solutions, we aim to empower woodworking professionals with the tools they need to achieve greater efficiency, accuracy, and profitability. We look forward to welcoming visitors to our booth and showcasing the future of woodworking technology."

VietnamWood consistently presents a valuable opportunity for industry professionals, woodworking enthusiasts, and decision-makers to witness Biesse's commitment to excellence and explore its latest offerings. Biesse invites all attendees to visit its booth at the exhibition and experience firsthand the innovative solutions that are shaping the woodworking industry.

Mr.Luigi De Vito , the European woodworking entire value chain focus on Automation,Sustainability and End-user experience

- 2023-09-21

Good morning, ladies, and gentlemen. I am pleased to be part of the Opening Ceremony of the 15th edition of the VietnamWood. First of all, I would like to thank the organizers for this delightful opportunity, and I would like to welcome all the delegates and present visitors. VietnamWood is the event of big interest because it correctly shows driving trends of our industry at the local and regional market. Vietnam remains an attractive destination to European investors in wood processing industry as the world’s leading furniture exporter. Wood-related business has always been centrally positioned. Nowadays, we are witnessing some promising projects which aim to turn our sector into a key economic one and promote the trademark of Vietnamese wood products domestically and internationally. Such approach continues to increase investor confidence in the country’s trade and investment environment. Despite these positive trends, the space for improving woodworking business is still large, the potential is here, and the momentum is now. In the coming 3 days, we will have the opportunity to

- boost sales

- build on existing customer relationships, but also

- establish new industrial synergies through the KNOWLEDGE EXCHANGE – a topic where European industry players can really make a difference......... Distinctive aspects of European woodworking industry because European woodworking sector has its own integrity and reputation. It has precise quality standards along the entire value chain. Main drivers are:

- Automation – which favours reduction of time and costs.

- Sustainability – new engine of manufacturing business models

- End-user experience - analysed through the adequate communication strategies. Automation is one of the central drivers because today the market is asking for information in real- time. Besides time and cost savings, automation can answer the raising challenge of customized (personalized) goods by applying various types of digital modeling. THE PROCESS IS COMPLEX AND AUTOMATION ASKS FOR STANDARDS - AND FOR SKILLED WORKFORCE. It is also important to define the right measure of automation - Where and how much to automate to best capture the over the long term. Sustainability is another leading topic in terms of the optimization of resources. In the woodworking sector, this concept is best captured within circular economy as the new business model which contributes value chain redesign and optimization. Even more, consumers’ habits are evolving in line with this concept. That’s why European business model takes into account the end-user experience - very important aspect because community acceptance of the technological solutions is always necessary for their duration and improvement in the future. Added value to the local economy. If we put together all these mentioned drivers, our knowledge, experience, and promising market potential, we could really make an added value for the local industry. It could help Vietnam:

- meet its expectations on woodworking:

- Improve woodworking manufacturing share in GDP.

- Raise its exports.

- Improve infrastructure and workforce skills leading to better macroeconomic performance. VietnamWood is the right occasion to set the ground for that. New Free Trade Agreement has helped see Vietnam rise to become the EU's largest goods trading partner in the ASEAN and rank as one of the EU market’s top 10 suppliers.

- Coming back to the importance of the VietnamWood

- The success of the innovation stands in the collaborative effort between wide range of stakeholders. By putting it in place we could reach higher competitiveness and attractiveness of our sector. Rich programme of the VietnamWood 15th edition made of numerous seminars and conferences, plentiful keynote speakers from influential industry associations will give us a good platform for further dialogue needed make clear guidelines for effective management practices. I am sure all of you will find the topic of your interest. Wish you successful and healthy stay in Ho Chi Minh. Thank you again and welcome to VIETNAMWOOD 2023!

TWMA held a corporate visit, YCM led the supply chain to make good use of knowledge management digital tools to promote the new generation of green transformation solutions

- 2023-08-07

The Taiwan Woodworking Machinery Association (TWMA) held a visit to YCM Machinery on August 4, led by Joe Chang, the chairman of TWMA. Chang said that the association had already conducted a visit to YCM in 2016, and it has become more affirmed in recent years. Into the machine step by step, each stage is very solid to do things well, and in each stage that requires transformation, we can make changes in line with the trend, so that the company can continue to improve and occupy a leading position. Chang emphasized that the most important thing at present is digital transformation, including suppliers, production lines and operation management. Although the industrial attributes of YCM Machinery and woodworking machinery are not exactly the same, the business philosophy of the enterprise is the same. During the process, I will definitely give you some advice. Inspired, because this is the future trend, Chang not only thanked YCM Machinery for providing member manufacturers with many opportunities to learn and watch models, but also appreciated the background of general manager Chen in business, who brought the company into a leap forward after taking over. The Great Leap Forward, the sound and colorful operation and management can be regarded as a model for the machine tool industry.

.jpg)

.jpg)

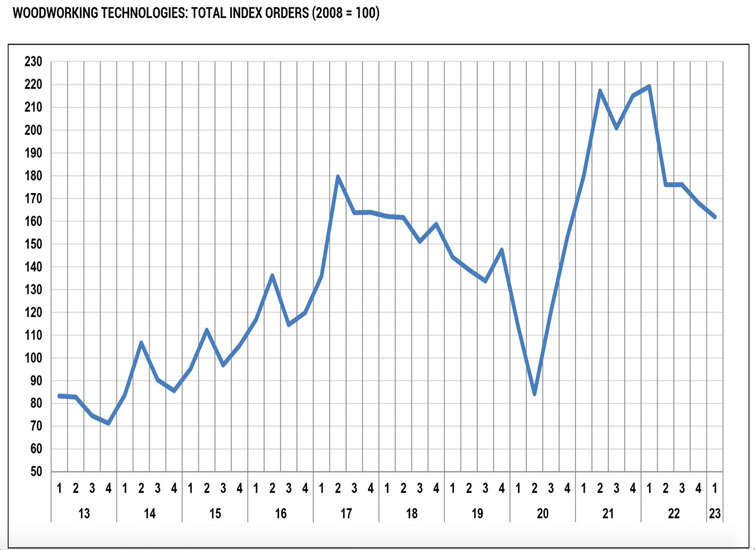

WOODWORKING TECHNOLOGY: BACK TO NORMAL?

- 2023-05-13

The first quarter 2023 confirmed a slowdown of orders for Italian woodworking and furniture technology. The quarterly survey by the Studies Office of Acimall (the association of Italian woodworking technology manufacturers) shows a negative trend for the fourth quarter in a row. This information must be evaluated accurately, especially considering the exceptional growth that characterized the second part of 2020 and the whole year 2021, recording a trend that has been unprecedented in the past decades. The slowdown that started in the second quarter of 2021 can be considered “physiological”, but the negative trend in the January-March 2023 period causes some worries. In the first quarter of this year, orders recorded a 25.7 percent reduction compared to the same period of the previous year, due to decreasing demand from international markets (down by 20.6 percent) and the significant shrinkage of the domestic market (minus 38.9 percent). It should also be noticed that the period of comparison, January-March 2022, was still an expansion phase, with significant growth rates in Italy and abroad, supported by public subsidies in many countries that, on one hand, really helped many industries overcome the consequences of the global sanitary emergency, but on the other, altered the normal evolution of the market. The reduction of orders is reflected onto the months of ensured production, dropping from an average of 6.1 months in October-December 2022 to 5.2 months in January-March 2023. The inflation trend – which in 2022 was in line with the economy in general – seems to be braking in the first months of 2023: the increase of sales prices for Italian wood and furniture technology was limited to 0.6 percent. Source:ACIMALL The opinions collected by the quality survey for the quarter under scrutiny reveal that the interviewed companies expect substantial stability of production (71 percent), while 24 percent indicates a growing trend and 5 percent a decrease. Employment is increasing according to 14 percent of the sample, stationary for 81 percent, decreasing for 5 percent. Available stocks are stable for 62 percent of the interviewees, while the remaining 38 percent is equally divided between those who indicate an increase (19 percent) and a reduction (19 percent). The forecast survey gives an overview of the scenarios that might emerge in the short term: 38 percent of the sample expect a substantial stability of orders from the foreign markets; such orders will decrease according to 38 percent and further increase according to 24 percent. Looking at the Italian market, 57 percent of the interviewees predict substantial stability, 19 percent increasing orders and 24 percent decreasing orders. Source:ACIMALL