SCM opens the new digital Home of woodworking innovation

- 2023-10-23

The Italian Group presented the latest innovations and the new Digital Control Room at Scm Headquarters in Rimini

More than 2,500 visitors from all over Europe, Asia, and North and South America, crowded the Scm Group headquarters in Rimini from 28 to 30 September to open the new Technology Center dedicated to the entire woodworking industry.

This new space has been enlarged to 4,000 square metres and presents technological and digital innovations for every machining requirement in the furniture industry, windows and doors production, timber construction and bespoke joinery.

The Technology Center was created as part of a redevelopment plan involving an additional 11,000 square metres of the entire Rimini industrial site.

Other investments, totalling an increase of 20,000 square metres, were made to increase production efficiency at the Scm sites in Monza, Piacenza and Siena, as well as at the Villa Verucchio site of the controlled company Hiteco, which specialises in electromechanical components.

The new Technology Center presents itself as the new digital home of woodworking innovation: every detail has been designed to offer the widest range of technologies and services and provide integrated, connected, flexible, more sustainable and optimised processes at each stage of secondary wood processing.

The event was an opportunity to discover the latest solutions developed by the Group which combine the strong technological skill for the production of solutions for furniture, doors and windows, timber construction and artisan joinery with the development of software and services, to accompany the client at each stage of their production process.

Among the new entries there were some applied to the CNC machining centres: Cargo, an innovative automatic system for loading and unloading doors and panels, and the new CAD-CAM programming software, Maestro lab.

Cargo was presented integrated with the morbidelli m200 pods&rails machining centre: it is a fully automated cell that requires no operator supervision, and it is unique in the market for its ability to continuously load and unload pieces in masked time while the machine performs drilling and routing operations. This exclusive solution allows for maximum efficiency by avoiding manual work phases and their associated costs and unproductive time, in addition to an unprecedented ease of use: both the machining centre and Cargo are directly managed with Maestro active HMI interface.

However, if it is true that the technology remains the heart of SCM’s experience, the software and services are increasingly the guarantor element of a continuous and shared relationship with the client. Maestro lab is the new cutting-edge CAD/CAM programming software for both the office and machine use. Intuitive and dynamic, it allows you to easily transform an idea into a finished product, thanks to intelligent and technologically advanced programming functions and more than 150 already integrated apps. So, from the office to the factory in a flash via an enjoyable and fast user experience.

The contextualised and continuous exchange of information from the machine to the cloud thanks to the IoT Maestro Connect platform means SCM can provide clients with rapid access to answers and specific advice which will support the operators and maintenance workers with their

challenges and needs for autonomy when using, carrying out maintenance and programming the machine and software. A specific area created inside the Technology Center demonstrates how data are transformed into bespoke assistance and advisory services of a proactive and predictive nature with a view to guaranteeing the client operational continuity thanks to the most evolved digital technologies and constant attention by the SCM Service team.

SCM continues to invest in the excellence of its customer service and, for the event, opened the doors to Autostore, its new automated spare parts warehouse. This innovation has allowed SCM to increase fivefold the pick-up speed of the codes and increase the number of orders handled within 24h by 26%. All this with an energy consumption of less than 0.1 kWh per robot, confirming the Group’s focus on sustainability.

Sustainability which also means ergonomics and ease of use, made available to the operators of all the SCM machines by the renewed eye-M control panel, which makes the operator’s work easier and offers a modular programming and a higher calculation power.

DingChang-Tool at Mokkietn Japan 2023

- 2023-10-19

We are glad to have interviewed with Mr.Matt Lin from DingChang-Tool at Mokkiten Japan to share the production and service from DingChang-Tool.

Mr.Lin said this is our first time participating in an exhibition in Japan, and we've been impressed by Japan's high level of manufacturing processing and precision requirements.We also would like to introduce Golden Eagle saw blades, insert knife, Finger joint cutter to the Japanese market.These are the products we have prepared to meet the market demands in Japan.

.jpg)

.jpg) We offer saw blades for wood cutting, non-ferrous metals, and metal cutting, as well as insert knife for woodworking and Finger joint cutter..etc.Our advantage is providing customers with stable quality and competitive pricing.If you need any assistance with the use of saw blades or cutting issue, please feel free to contact us.

We offer saw blades for wood cutting, non-ferrous metals, and metal cutting, as well as insert knife for woodworking and Finger joint cutter..etc.Our advantage is providing customers with stable quality and competitive pricing.If you need any assistance with the use of saw blades or cutting issue, please feel free to contact us.

Anderson's automation solutions to wood industry at Mokkiten Japan 2023

- 2023-10-15

Oct 07, the last day of Mokkiten Japan 2023, we are very glad to have interview with Mr. Shawn Teng , the manager of Anderson group from Taiwan to share the Anderson’s automation solutions to wood industry. Mr.Teng said that Anderson, to keep developing in Automation solution for different customers with fitting integration for the many years. With Anderson engineering team, we work together with each customer, to understand more about their current manufacturing processes and to improve it by developing new software features , mechanical devices and PLC programming, furthermore, we work with several different suppliers for automated feeding and pick-place units such as Robotic, AGV, suction systems etc. to provide customer with Anderson total solutions. Automation to Anderson is each project for every customers and we work closely, so when you have new ideas or issues, just talk to Anderson, we’d be more than glad to help.

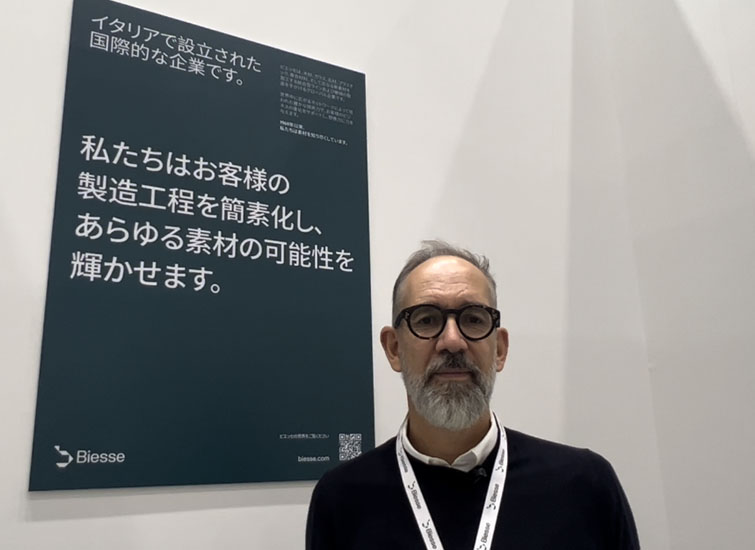

New Biesse Branding at Mokkiten Japan 2023

- 2023-10-14

Here is the second day of Mokkiten Japan 2023. We are very glad to have interview with Mr.Raphael Parti Chief Marketing & Communications Office of Biesse form Italy. NewsWin : Hi , Raphael , can you tell us about the new Biesse branding? Raphael : Of course with great pleasure.You know that the global international ,the job of our customers easier now and in the future. So that is being a reorganization in the company evolution based on two aspects. The fact that we concerned for not only wood but many different material sectors , glass and stone primarily and our customer is building furniture are using not only wood but glass and stone so this is one aspect. The second is to be closer to be closer to our customers. We have been exporting our machines since many years. We've been present in the different countries for long now we are also here in Japan. We are opening a new subsidiary, a new building with a showroom in order to give a possibility to the customers to have a hands on experience on our solutions to understand what is the potential of their business and how they can actually grow with Biesse. This is the reason why the new branding. It's a new company and you brand based on multimeteriality an international approach, as we say, we are international natives, for this reason. a new logo, a new color, and a better way, a new way of engaging with our customers. By NewsWin

Total Solutions from SK Global

- 2023-10-13

Here is the last day of the Mokkiten Japan 2023. We are very glad to have interview with Mr. Cliff Chang, CEO of SK Global from Taiwan, NewsWin : Hi, Mr. Chang , can you tell us about SK Global ‘s production features and service? Mr. Chang:Yes , of course .SK Global is a company specializing in the turkey project like automation of the Glued-laminated timer . In Japan I think the labor cost is higher. we have many customers they are looking into a total solution for integrating all kind of machine into the same line in order to produce the gluename and CLT. We are the company we have all the designing of the whole line and we have all the software program can provide total solution to all these Japanese customers. By NewsWin

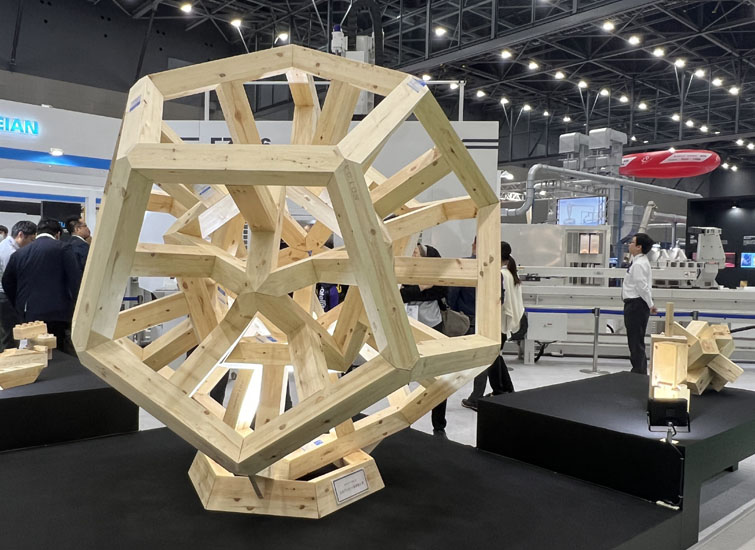

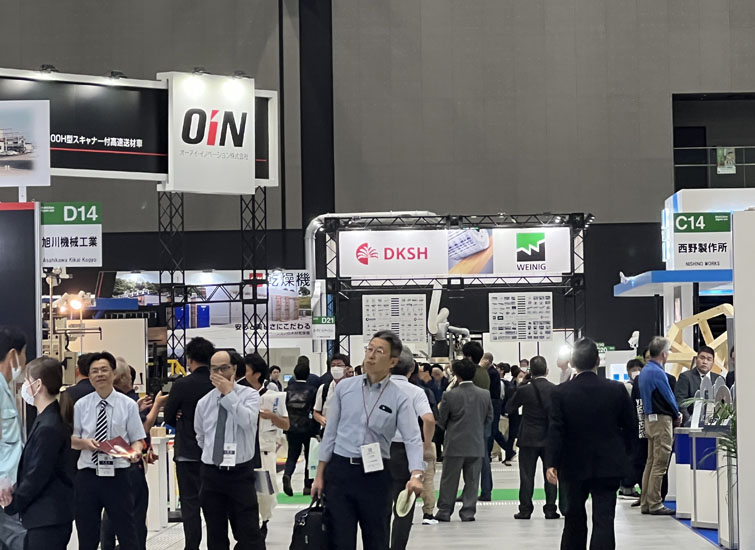

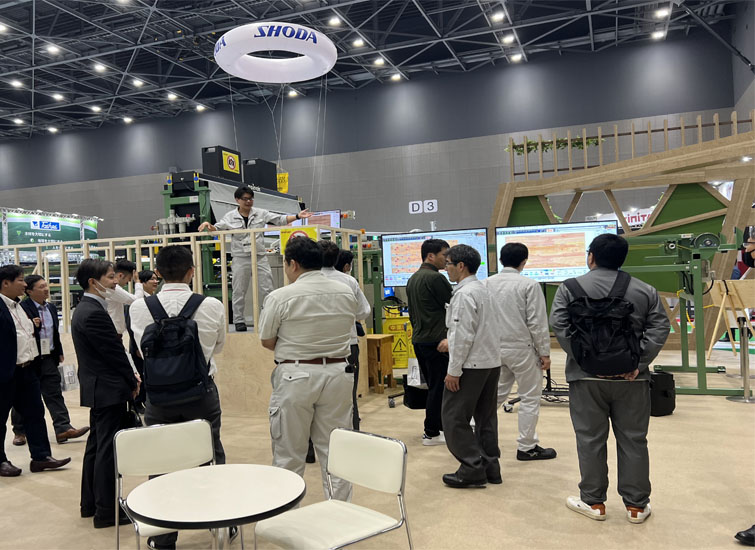

Mokkiten Japan 2023 shows“Work that connects forests and people”

- 2023-10-10

Mokkiten Japan grand opened on Oct 05,2023, This is the 46th as the largest general exhibition of wood machinery in Japan.

There were 155 companies and organizations exhibiting and 1,063 booths, making it one of the largest in the past 20 years.

This time, it was held at the newly established Port Messe Nagoya New Exhibition Hall No. 1. The New No. 1 Exhibition Hall is one of the largest in Japan, with approximately 20,000 square meters of pillarless space, and is directly connected to “Kinjofuto Station” on the Aonami Line, making it a very convenient exhibition venue for visitors.

The theme of this exhibition is “Work that connects forests and people”. Japan has abundant forest resources. It is our urgent task to use this renewable resource carefully. One of the answers is the utilization of wood by wood processing machines. A wood processing business that connects precious forest resources, which are the blessings of nature, to people’s lives. That wooden skyscrapers are being built one after another, the wood processing industry is needed to realize a sustainable society. Please see “Work that connects forests and people”.

In order to make this exhibition worthwhile for everyone, the organizer made it a big event where cutting-edge technologies and solutions that support our lives and create a prosperous future society, such as all technologies that utilize DX for the future of the wood industry, advanced image processing, AI, IoT, and robots that solve labor shortages, will come together. In addition to domestic manufacturers and sales companies, many overseas manufacturers will gather to provide visitors with a large amount of cutting-edge information on cutting tools, paints, adhesives, drying, dust collection, construction, furniture hardware, DIY, and related equipment, along with newly developed processing technologies such as lumber, plywood, laminated lumber, woodwork, pre-cutting, ceramic siding, and resin.

The exhibitors and machinery form Taiwan are Anderson group, Kuang Yung, Leadermac , CPT , SK Global , Joway ,CYWWM,BOARK, DING_CHANG tool, TAI CHUN,GAU JING, INNOVAOTR, CKM,YUAN AN, NewsWin Media etc.

The exhibitors and machinery form Taiwan are Anderson group, Kuang Yung, Leadermac , CPT , SK Global , Joway ,CYWWM,BOARK, DING_CHANG tool, TAI CHUN,GAU JING, INNOVAOTR, CKM,YUAN AN, NewsWin Media etc.

.jpg)

.jpg)