SCM in the spotlight at IndiaWood

- 2024-01-30

IndiaWood will be the opportunity for SCM to present its cutting-edge technologies and services and to announce the next opening

of a new Subsidiary in Bengaluru.

22-26 February 2024

Bengaluru International Exhibition Center (BIEC)

Hall 4, Stand M 104

The 13th edition of IndiaWood is coming and SCM, a global leading producer of secondary woodworking machinery, is ready to illustrate a cutting-edge selection of its best technological solutions and services for the market.

The Italian Group will attend the Asian leading international trade fair confirming the strong attention given to Indian region, the strategic investments done to strengthen SCM’s direct presence in this area and the will of being an all-around business partner for both industrial and artisan companies in the woodworking and furniture manufacturing sectors.

The varied proposal of technologies on demonstration is particularly suited to Indian customers and meet every machining requirement both in panel and solid wood processing.

TECHNOLOGIES HIGHLIGHTS

Here are just some state-of-the-art technologies that visitors will be able to find out with the SCM team’s experts.

Cnc machining centers: morbidelli p200

This universal cnc machining centre is conceived to satisfy any drilling, routing and edgebanding requirement. Just a few clicks allow to design and manufacture pieces of any shape and easily apply several typologies of edges.

This “All-in-one technology” solution is unique on the market in having an unrivalled price-performance ratio and in offering several advantages.

Morbidelli p200 also offers a superior quality thanks to the edgebanding unit which can process edges up to 80 mm height. Other advantages are the head borings fitted with RO.AX spindles with greater rigidity and a rotation speed up to 8000 rpm, the 5-axis JQX electrospindle for an unparalleled finish and the FAST 14 tool change that ensures a tool change in less than 15 seconds.

The HE-PODs, synonymous of flexibility and innovation, bring the third dimension to the worktable surface. The machine can lift up the pieces to be processed and avoid unnecessary repositioning, making the most of the worktable size and reducing production cycle times by 30%.

The Maestro edge software is ideal to manage and optimise the entire routing, drilling and edge banding process of panels and shaped components. The application guarantees maximum simplicity, unparalleled performance levels and a considerable reduction in the production cycle times.

This “All-in-one technology” solution is unique on the market in having an unrivalled price-performance ratio and in offering several advantages.

Morbidelli p200 also offers a superior quality thanks to the edgebanding unit which can process edges up to 80 mm height. Other advantages are the head borings fitted with RO.AX spindles with greater rigidity and a rotation speed up to 8000 rpm, the 5-axis JQX electrospindle for an unparalleled finish and the FAST 14 tool change that ensures a tool change in less than 15 seconds.

The HE-PODs, synonymous of flexibility and innovation, bring the third dimension to the worktable surface. The machine can lift up the pieces to be processed and avoid unnecessary repositioning, making the most of the worktable size and reducing production cycle times by 30%.

The Maestro edge software is ideal to manage and optimise the entire routing, drilling and edge banding process of panels and shaped components. The application guarantees maximum simplicity, unparalleled performance levels and a considerable reduction in the production cycle times.

Edgebanding: stefani kd

Heavy duty and versatile edge bander for working different types of panels even with delicate surfaces thanks to the upper belt presser.

The working speed of up to 20 m/min and the processing of solid wood strips up to 12 mm thick make this edge bander ideal for industrial companies that need to produce panels in large quantities and with extreme quality.

The SGP glue pot, supplied as standard, with the special non-stick plasma treatment allows the use of two different types of glue, EVA and PUR, for perfect edgebanding quality even on the latest generation panels. The optimal glue dosage and the special spreading roller ensures a perfect glue line. The SGP glue pot can be loaded both manually and with automatic pre-melters and the glues can be interchanged thanks to the automatic glue change/cleaning cycle with unloading onto the removable collection box. The possibility of having 2 premelters at the same time, the QMS-P for EVA glue and the PU BOX L for PUR glue, always guarantees the best glue quality.

Wide belt sanders: dmc sd70

The dmc sd range of high-tech sanding solutions is ideal for small-size manufacturers who look for effectiveness, efficiency and high level of versatility. In fact dmc sd 70 is perfect for different types of machining. In the furniture sector this wide belt sander is ideal for calibrating MDF, plywood and solid wood as well as sanding veneered panels and finishing painted surfaces.

The SGP glue pot, supplied as standard, with the special non-stick plasma treatment allows the use of two different types of glue, EVA and PUR, for perfect edgebanding quality even on the latest generation panels. The optimal glue dosage and the special spreading roller ensures a perfect glue line. The SGP glue pot can be loaded both manually and with automatic pre-melters and the glues can be interchanged thanks to the automatic glue change/cleaning cycle with unloading onto the removable collection box. The possibility of having 2 premelters at the same time, the QMS-P for EVA glue and the PU BOX L for PUR glue, always guarantees the best glue quality.

Wide belt sanders: dmc sd70

The dmc sd range of high-tech sanding solutions is ideal for small-size manufacturers who look for effectiveness, efficiency and high level of versatility. In fact dmc sd 70 is perfect for different types of machining. In the furniture sector this wide belt sander is ideal for calibrating MDF, plywood and solid wood as well as sanding veneered panels and finishing painted surfaces.

The configurations can vary from two or three units, combining roller, pad, superfinishing, brush units as well as crossbelt unit.

In recent years, the dmc sd range has also been enhanced with new solutions that are unique on the market such as the led bar to optimise belt wear, the interchangeable brush unit to produce different machining processes (paint, structuring, chamfering etc.) and lastly the new eye-S control panel with Maestro active interface.

IndiaWood visitors will also be able to find out other SCM technologies for windows and doors manufacturing as well as joinery machines, world leader for top of the range, unique performance and continuous innovation.

The configurations can vary from two or three units, combining roller, pad, superfinishing, brush units as well as crossbelt unit.

In recent years, the dmc sd range has also been enhanced with new solutions that are unique on the market such as the led bar to optimise belt wear, the interchangeable brush unit to produce different machining processes (paint, structuring, chamfering etc.) and lastly the new eye-S control panel with Maestro active interface.

IndiaWood visitors will also be able to find out other SCM technologies for windows and doors manufacturing as well as joinery machines, world leader for top of the range, unique performance and continuous innovation.

SCM EXPANDS REACH WITH A NEW SUBSIDIARY IN BENGALURU

IndiaWood will also be the opportunity for SCM to announce the opening of a new Subsidiary in Bengaluru in April-May 2024. This is a great news for Indian customers and as anticipated by the new Country Manager, Kunal Roy, “SCM has made strategic investments to provide local businesses in the woodworking industry with an even more extensive and all-round assistance not only In India, but in the whole region including Sri Lanka, Bangladesh, Bhutan, Nepal & Maldives”. “We are in process of expanding our Sales&Service infrastructure in India to cater to the entire region. We have executed some very prestigious projects in 2023 across various regions in India, such as Maharashtra, Gujarat, Tamil Nadu&Telangana and Delhi. We are continuously expanding our service team across India to ensure that we are able to provide a highly specialised, fast and reliable service support to any customers in the region”.

IndiaWood will be an ideal opportunity to meet the SCM team. “We are looking forward to welcoming and meeting Indian customers at our booth, in order to demonstrate SCM products and services best suited to their machining requirements”.

Source: SCM Gruop

AN EXCELLENT 2023 AND MANY NEW PROJECTS FOR 2024

- 2024-01-26

“We are optimistic: there will always be room for companies that offer smart and effective solutions through an international network”. This is the comment of both Stefano and Riccardo Mauri – owners of Giardina Group, a world leader in painting and surface finishing technologies – regarding the 2023 results. Seventy employees, a turnover of around 20 million euros, a vast range of solutions stemming from a long-lasting and well-established partnership with companies that – in every corner of the world – operate in the painting sector, deep relationships that have enabled the Italian company to reach an export share close to 95% of its total output. A consolidated presence in many international markets that has made it possible to acquire an extensive set of orders for 2024 as well: indeed, after a brief period of uncertainty, demand has returned to good levels, with the possibility of planning key deliveries up to the beginning of 2025, so as to have the energy needed to include any urgent requests in production programmes. Precisely the ability to respond quickly to customer requests is one of the keys to the growing success of Giardina Group. Its production focuses precisely on this aspect, as the order for a machine or system is not always something planned and the above often proves to be a strategic tool for tackling certain orders. This strategy includes the availability of stand-alone machines that can be installed and tested in a few weeks, so as to help clients be more competitive. On the other hand, 2023 saw the confirmation of Giardina Group's vocation for custom-made systems. This has always been the core business of the company, which continues to be among the privileged partners for this type of demand, thanks to an even more direct involvement in phases part of the painting process: handling and sanding. “We are building an actual network also at a technical-production level, thanks to which we can also offer edge and profile sanding solutions to those who want our quality, thanks to Destefani, but also automation, logistics and handling solutions”, says Riccardo Mauri, co-owner and technical director at Giardina Group. “Offering technology involves full attention to the customer's needs, as well as to the big issues that the industry must be able to responsibly address today. There is much talk about sustainability, for example, a topic that has always been a daily challenge for a sector like ours. Painting-related activities have alarmed, often rightly, many. The situation is very different today and we, as technology manufacturers, are the first to implement a whole series of innovations and solutions which not only comply with the most stringent environmental protection regulations, but also regulations that guarantee aesthetic quality and resistance that are even better than in the past. Right from the early design stages, each machine, each system is studied and defined so that it has the lowest possible energy requirements and very low emission levels, whilst always guaranteeing finishes of the best quality”. “Skills and quality that we show at work in our Giampiero Mauri Innovation Centre, a laboratory/show room where technicians and customers from all over the world come to test their products, to paint them, to verify the quality that our machines and our systems can help provide”, says sales director Stefano Tibè. “We are launching new integrated hospitality projects for customers, offering an increasingly broader range of demos and training on every aspect of finishing, for which we receive many participation requests every year. Besides, we have all realized that now it is not enough to design and build good machines, but you need to provide a comprehensive, total service that enables customers to exclusively focus on their own business, delegating all the issues related to the various processing cycles to trusted suppliers”. Therefore, companies that do not limit themselves to manufacturing, but that constantly interact with all the players in the supply chain, becoming bearers of ideas and values: it is no coincidence that the Giardina Group Academy will be launched in 2024. This is meant to be an actual ‘school’ that will be carried out in partnership with Catas, the most important testing laboratory for the wood and furniture supply chain in Europe. It will start out in Brazil, a country that is proving to be increasingly strategic for Giardina Group. “We want to prove that sharing knowledge can open new avenues in markets where there is still a lot to discover”; added Stefano Mauri. “An initiative that has been in our plans for some time and which we want to turn into an actual model to export to other countries, because Italian technology must increasingly act as a complex response, in which the machine is only one of the components necessary to guarantee a service. This is what businesses want today: service, the ability to have tools that are easy to use, supported by actual partners not only at the time of sale, but also and above all at the assistance stage, in continuity with the relationship established, with hardware and software updates acting as a support to accept new orders and redefine competitiveness levels on a market clearly constantly on the move. This all leads us to face this economic season with peace of mind. A season in many ways influenced by excellent results in terms of turnover but also by greater uncertainties in terms of orders. We find ourselves operating in an economic-social context full of complexity that we recommend many stand back and watch for a little while longer, waiting for at least some of the many clouds that still darken the horizon to disappear”. A chapter that underlines with a precise strategy the commitment of Giardina Group in markets all over the world. It enabled the company to consolidate a strong network of stable representatives to reiterate a ‘quality proximity’ to its increasingly numerous customers. Giardina Group in a nutshell Seventy employees, a turnover of around 20 million euros, an export share of close to 95% and know-how that has resulted in an extremely comprehensive catalogue: from beam impregnation to the treatment of ‘Jumbo’ glass sheets, from profile finishing to sophisticated robot systems for coating windows and doors or furniture building materials. Today Giardina Group stands for design, development and manufacture of machines and full coating systems (roller, film, spray and vacuum); automated and robotic lines with hot air, UV or microwave drying systems; overhead lines to coat windows and doors or three-dimensional pieces, spray booths and special systems and – with Destefani – edge and profile sanding solutions.

New SCM subsidiary in Slovenia

- 2024-01-16

The launch of this new subsidiary is aimed at providing a direct, punctual and highly specialised sales and service support to woodworking businesses

in Slovenia and Serbia. The SCM team will also work in sync with dealers in Croatia and Bosnia and will be a benchmark for the entire Balkans area.

SCM continues making investments to guarantee a capillary and direct presence in the most strategic international markets.

This mission is met with the opening of a new SCM subsidiary in January 2024, based in Trzin, near Ljubljana in Slovenia. It is being opened to directly follow clients in both the Slovenian and Serbian markets, preserving their local characteristics and identities. In addition, it will work alongside and provide even more efficient support to the dealers already operating in Croatia and Bosnia.

The new subsidiary, SCM’s first in the Balkans, will become a benchmark for the entire region where, for a number of years now, the wood-furnishing industry has recorded a more than positive trend and includes businesses that are increasingly technologically advanced.

The facility will have an exclusive 1,500 square metre Technology Center offering a wide and varied range of the latest SCM innovations, with machinery and services strongly in line with the production requirements of this market.

SCM will also be able to rely on a team of technicians and sales engineers who are highly specialised in all the application fields of secondary wood processing: from the joinery workshop to large furniture industries, right up to windows and doors and timber construction which is recording strong and continuous growth throughout the region.

Being able to interact directly with the SCM team also means taking a closer look at, and selecting from, an exclusive offer of technologies and software which represents the widest range of wood processing solutions internationally.

There are also considerable advantages for customer care: the client can take advantage of more punctual after-sales support both with regard to technical maintenance and management of spare parts, as well as having rapid access to the numerous digital services enabled by SCM’s IoT platform, Maestro connect for an ever more efficient proactive and predictive assistance.

“With the opening of this new branch, businesses in the industry will benefit from an all-round commercial and technical partnership - says Lorenzo Trolese, SCM Country Manager for Balkans area -. Our team, which will continue to grow, even in the coming months, with the addition of new sales and services resources, can provide the client with all the support, consulting and training needed to optimise its production processes. This represents a huge leap in quality for this market because it can continue along a direct line and an ever more efficient and direct service, from pre to post sales”.

Source: SCM Group

Source: SCM Group

The trend of furniture industry

- 2024-01-12

For many years, Taiwan has stood tall as a bastion of manufacturing, with our furniture industry being a hallmark of that legacy. Taiwan's furniture sector has achieved notable successes, securing a firm foothold on the global stage. However, given the evolving global economic landscape, inflation, and changing consumer preferences, it's imperative for our manufacturers to consistently adapt and innovate to remain at the forefront. We are glad to invite Mr.Sam Chen , Honorary Chairman of the Taiwan Furniture Manufacturer Association(TFMA), to express his views on the future development of Taiwan's furniture industry. The highlights are as follows: Environmental Sustainability: As global awareness of environmental issue increases, there’s an escalating demand for sustainable and eco-friendly products. Embracing green materials and methodologies not only safeguards our planet but also aligns with international market demands. Smart Home Furniture: The technological surge, paired with the internet’s ubiquity, has opened new horizons for the furniture domain. Future furniture, endowed with smart sensors, could offer adaptability and automation, enhancing both user convenience and comfort. Moreover, virtual reality might revolutionise furniture design. Customization: Tailor-made furniture is poised to be a dominant trend. A growing number of consumers, particularly the younger demographic, seek to articulate their unique identities through their furniture choices. Global Market Outreach: While Taiwanese furniture has garnered international acclaim, there’s ample room for growth. Engaging in global furniture expos via our association can further amplify our export endeavours. Educational Initiatives and Skill Development: To cater to emerging demands and innovate, Taiwan must champion the education of the ensuing generation, fostering top-notch designers that elevate our industry's global standing. The Rise of the Pet Kingdom: 2022 data highlighted an interesting trend: the number of registered pets in Taiwan outstripped newborns. As pets increasingly become beloved family members, the realm of pet furniture beckons as a burgeoning market opportunity. In summation, while the horizon for Taiwan’s furniture sector remains luminous, it behoves us to relentlessly innovate, attuning ourselves to the mutable market dynamics and consumer desires. Together, let us navigate this journey with vigor. Source: TFMA

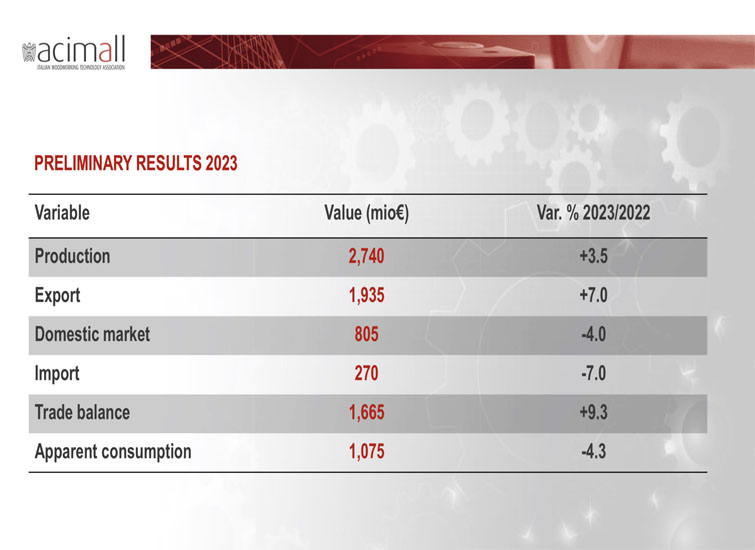

TECHNOLOGY FOR WOODWORKING AND THE FURNITURE INDUSTRY: ANOTHER POSITIVE YEAR IN 2023 (plus 3.5 percent)

- 2024-01-11

The preliminary balance of 2023 drafted by the Studies Office of Acimall shows 3.5 percent growth of production compared to 2022. So, despite a trend of orders that was much less satisfactory than the excellent results of the past years, the companies had and still have a strong order backlog, allowing them to increase their revenues also in the year that’s going to end. After the 5.3 percent increase achieved in 2022 over the record year 2021, this trend indicates the full health of the industry companies, who had the opportunity to invest and strengthen their position in Italy and, according to tradition, all over the world. The value of production reached up to 2.74 billion euro, net of inflation, but still an all-time record for the woodworking machinery industry in a period when all mechanical industry domains, machine tools above all, are experiencing the same situation. Export – which account for approximately 70 percent of total revenues – increased by 7 percent (1.935 billion euro in value), while sales on the domestic market are falling (805 million, down by 4 percent from 2022), also reflected by the significant decrease in import (270 million in value, minus 7 percent compared to the previous year). The Italian market is going through a less positive period and it could not be otherwise, considering that the investments made by users in recent years have reached significant levels, actually saturating the equipment fleets. Therefore, the reduction is natural and expected, and it must be evaluated accordingly. The reduction of apparent consumption amounted to 4.3 percent, down to 1.075 billion euro, showing the consistently strong demand of wood and furniture technology in Italy, which remains the fourth global market after China, the United States and Germany, and before Vietnam at number five. It is also worth noticing that, also in 2023, the industry of wood and wood-based material technology maintained an excellent performance in terms of trade balance, with an active result by 1.665 billion euro, 9.3 percent higher than in 2022; this is definitely one of the most significant results in the entire landscape of machine tools and a great contribution to the total Italian result. THE YEAR 2024 As mentioned, for a few quarters now, the woodworking machinery industry has moved back to more “normal” values, after the booming trend of recent years, and it is expected to follow the same trend also in 2024. “Such values can hardly be estimated today, due to the tragic international events we all know, that might have a heavy impact on the global economy”, said Acimall’s director Dario Corbetta. “Our industry is also subject to ups and downs, with positive periods alternating with less satisfactory ones: the news – so to say – is that the growth in the past years was so powerful to generate a peak, a strong discontinuity that will require a slow return to normal, hence the persistence of negative values over a long time, though with lower rates”. “However, there is a feeling that the industry is worrying excessively for what can be considered a natural slowdown”, Corbetta continued. “2023 figures are showing this, and today, the companies are definitely much stronger in terms of financial capacity and organization, compared to previous, much more difficult periods: as a result, they will be able to face a business reduction that we can call “normal”, though apparently magnified by the extraordinary results of the previous three years”. INDUSTRY 5.0 Undoubtedly, in recent years, the Italian market has been “stimulated” by measures that encouraged different types of investments. And also for the next season, there are variables that might affect the results to a significant extent. We are referring to measures included in the “Industry 5.0” plan, within the framework of the national recovery and resilience plan (Pnrr), approved by the European Commission as consistent with the “REPower EU” plan, aimed at accelerating the transition of EU countries to clean power , and more generally, at the adoption of energy-saving measures. The new facilitations introduced by Italian financial institutions fit into this context, supporting investments that meet the standards of connectivity and integration into the enterprise management networks envisaged by “Industry 4.0”, and ensuring less power-hungry operations in addition. “For the 2024-2025 period, companies will have access to tax credits for a total value of 6.3 billion euro, to be added to the benefits of “Industria 4.0”, a plan created to support all measures for the energy efficiency of machines and plants”, Dario Corbetta said. “The shrinkage of recent months might have been driven by many companies which decided to wait for the full deployment of the new measure before making new investments. Saying that such measures are “appreciated” is a clear understatement, despite their “elastic” effect on demand. Longer-term policies that do not overlap year after year would certainly have more enduring and structural effects on demand trends”. There are elements for cautious optimism, and for sure, Xylexpo 2024 – the biennial international exhibition of technology for the wood supply chain organized by Acimall to be held at FieraMilano-Rho next May 21 to 24 – comes right on time to help potential customers and users leverage the innovation in terms of energy efficiency that will characterize the entire portfolio. Source:ACIMALL

“High turnover.

- 2024-01-04

We were honored to interview Joe Chang , the chairman of TWMA to share and his thoughts on the future of woodworking machinery in 2024. The key points here are as follows: In the years 2020 and 2021, Taiwan's woodworking machinery industry experienced a compound growth of 54%. However, the period from 2022 to 2023, there was a significant compound decline of nearly 70%. This decline is not limited to the woodworking machinery industry but extends to Taiwan's overall exports, which have been in a continuous downturn for 16 months since March 2022. The persistent interest rate hikes by the U.S. Federal Reserve is a primary driver of the global export recession, compounded by the post-COVID-19 changes in the global economic landscape. These changes include the restructuring of raw material supply chains, the U.S.-China trade tensions, and geopolitical shifts altering the existing model of global production and manufacturing bases. Additionally, future trends such as net-zero emissions, ESG requirements for businesses, and the growing influence of AI will play a crucial role in the future development of the woodworking machinery industry. Furthermore, the rise of woodworking machinery in mainland China has already impacted the global proportion of woodworking machinery exports (China's exports surpassed Taiwan's in 2008, accounting for approximately 7% of the global export proportions. By 2014, they exceeded Italy's, reaching around 18%. In 2020, China's woodworking machinery exports surpassed Germany's, and it has constituted approximately 26% of the global export proportions in 2023). Facing these various trends and challenges, the future of Taiwan's woodworking machinery industry requires strategic considerations. In addition to revisiting the suggestions made at the beginning of 2023 (1. Identifying the company’s core values and “niche markets". 2. Implementing effective "knowledge management" extended to "lean management" and "digital transformation". 3. Maintaining a mindset and concept of "continuous improvement" and "customer satisfaction"). I believe we should focus on several key developments: 1. Utilize "digital tools," such as chatGDP, for tasks like drafting development letters, press releases, meeting records, customer visits, and data consolidation. The use of digital tools can enhance the integration of "knowledge management" and reduce the workload of relevant personnel. 2. Integrating "digital marketing" with "physical exhibitions" aims to optimize the marketing processes of "pre-exhibition," "during the exhibition," and "post-exhibition" at a lower cost. While customers may feel more assured seeing physical machines at exhibitions, digital marketing can precisely promote the exhibition, connecting with potential clients and significantly reducing transaction times. 3. Being attentive to trends, policies, and information related to net-zero emissions will enable the company to respond promptly when called upon to act. 4. Addressing the challenges of Taiwan's declining birthrate and labor shortage by collaborating with the government's policies for attracting foreign talent and seeking the necessary expertise for our own companies. These are irreversible trends. Adequate preparation will better position us to adapt to the unpredictable future, and our collective pursuit should be focused on achieving "high net profit" rather than merely “high turnover."