Current Status of Global Woodworking Machinery Industry

- 2023-02-25

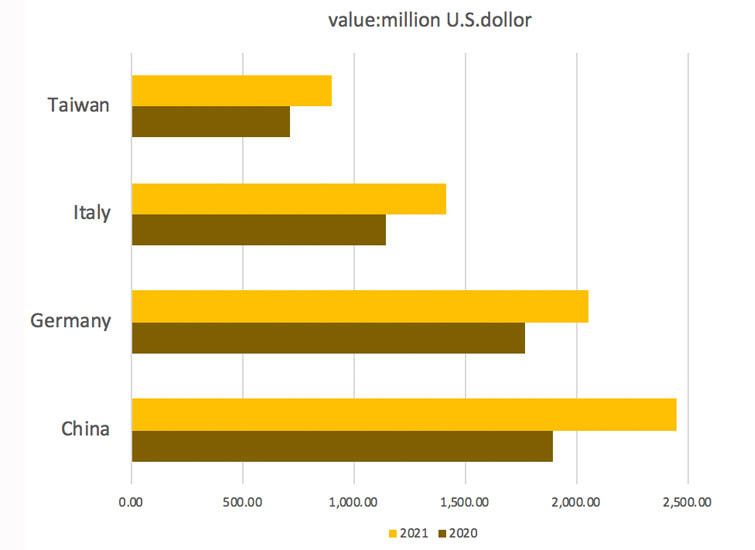

According to ITC (International Trade Centre) data ( Figure 1 and Figure 2), the global woodworking machinery export value in 2021 is about 9.74 billion US dollars, ranking first with mainland China, accounting for 25.3% of the global woodworking machinery export value (2.46 billion U.S. dollars), followed by Germany 21% (2.05 billion U.S. dollars) and Italy 14.5% (1.41 billion U.S. dollars). Taiwan's woodworking machinery exports rank fourth in the world, with an export value of about 900 million U.S. dollars, accounting for the world's The export ratio is 9.3%, and its strength should not be underestimated. The industry is also actively breaking through the development bottleneck, moving forward with "digitalization and intelligence" as the development direction, and striving to expand brand awareness in the international market.

Linear systems from igus as space-saving solution in award-winning furniture design

- 2023-02-03

drylin linear guides ensure a clean pull-out in the multifunctional cube SQR

Living, working and cooking in confined spaces is currently part of everyday life for many people worldwide. This is why more and more practical furniture such as the multifunctional cube SQR is in demand. A square solution that combines kitchen, workplace and dining table. To create plenty of storage space, the inventor relied on the lubrication-free and long-lasting drylin linear guides from igus.

At the end of 2016, Daniel Pracht lived in a small flat with no kitchen. The then budding master carpenter developed a practical quadratic solution: the SQR. A multifunctional cube with an extendable induction area, with which one or more persons can not only cook, but also stay, work and live in a compact space. Perfectly suited, especially at times when a home office is more than ever, the order of the day. To create a lot of storage space, the inventor was looking for a pull-out solution. Normal roller guides took up too much installation space and did not meet the requirements for a simple and elegant design. Daniel Pracht found what he was looking for in the drylin linear systems from igus: "The guides convinced me right from the start, both in terms of design and smooth operation."

.jpg) Industry and furniture technology = functionality and design

When choosing the drylin WSQ linear system, one decisive criterion was not only the functionality - the wear-resistant and long-lasting opening and closing of the drawers - but also the processing of the rails. "The combination of the aluminium of the rail and the oak of the cube complements one another, which was very important to me. Just like the square shape of the guide", explains Pracht. Each of the five drawers contains two guides. Liners made of the high-performance iglidur J200 polymer ensure smooth operation. It is lubrication-free and maintenance-free, thanks to the use of solid lubricants. A great advantage in potential contact with food. Furthermore, dirt and dust cannot adhere to the bearings. The guides and bearings are easy to clean with household chemicals. An all-round hygienic solution.

Quadratic and compact design convinces professional juries

The concept convinced not only the inventor himself, but also a wide audience. Daniel Pracht won the Design Prize at the exhibition of masterpieces at his school. After that everything went very fast. Due to the increasing attention of his furniture, he registered a utility model protection, secured the brand name "SQR" and founded BODI e.K. as the registered merchant of a new distribution channel for his special piece of furniture. Pracht took part in the Red Dot Design Award in 2018 and won the award. In 2019 he was nominated for the German Design Award.

Source:igus Taiwan

Industry and furniture technology = functionality and design

When choosing the drylin WSQ linear system, one decisive criterion was not only the functionality - the wear-resistant and long-lasting opening and closing of the drawers - but also the processing of the rails. "The combination of the aluminium of the rail and the oak of the cube complements one another, which was very important to me. Just like the square shape of the guide", explains Pracht. Each of the five drawers contains two guides. Liners made of the high-performance iglidur J200 polymer ensure smooth operation. It is lubrication-free and maintenance-free, thanks to the use of solid lubricants. A great advantage in potential contact with food. Furthermore, dirt and dust cannot adhere to the bearings. The guides and bearings are easy to clean with household chemicals. An all-round hygienic solution.

Quadratic and compact design convinces professional juries

The concept convinced not only the inventor himself, but also a wide audience. Daniel Pracht won the Design Prize at the exhibition of masterpieces at his school. After that everything went very fast. Due to the increasing attention of his furniture, he registered a utility model protection, secured the brand name "SQR" and founded BODI e.K. as the registered merchant of a new distribution channel for his special piece of furniture. Pracht took part in the Red Dot Design Award in 2018 and won the award. In 2019 he was nominated for the German Design Award.

Source:igus Taiwan

The online furniture market has become the mainstream, and the industry is expected to continue to grow

- 2023-01-12

We were honored to visit the chairman of Taiwan Furniture Manufacturer Association (TFMA) Sam Chen to ask him for his views on the furniture industry.Following is the key point of his statement .

.jpg) For domestic demand, the sales of imported furniture and other retail sectors increased by 14.16% YOY in the first half of 2020. It showed that, under the epidemic, more people increased their budget in healthy family lifestyle, driving growth for related industries. Since 2021, with the accessible vaccines, the world has developed a way of life that coexists with the virus. Entering the post-pandemic era, we found that a M-shaped consumer preference has shown in furniture market. Even though global market was suffered from the increased cost due to the shortage of labor and materials, the bantique furniture market has been growing. Thus, there still have huge potentials in luxurious bantique furniture sector.

On the other hand, environmental protection, energy saving, and carbon reduction are still the mainstreams in the market. Enterprises can achieve the goals through eco-friendly production, recyclable materials, or eco-materials, such as popinac or bamboo. Meanwhile, custom furniture service with AI virtual technology, multifunctional furnitures with composite structure for small spaces are ongoing trends. And, under the lower birth rate in East Asia, pet furniture become more popular. With its huge potentials, more furniture malls and exhibitions has launched pet segments.

In regards of export market, since 2016, the global furniture value had gradually recovered to $490 billions along with the world economy as of 2019. Since then, the market has been steady growth. In developed countries, citizens have stronger purchasing power that would make them pursue higher quality living spaces, generating a steady furniture demand from redecorating old houses or rental houses.

In developing countries, the increasing number of people in cities has led to the expansion of housing demand and the demands for furniture. Meanwhile, the rapid economic development of emerging market has increased residents' purchasing power. As a result, people have more capabilities and more desire to seek better living condition, which would drive continuous growth. Industry Consulting Expert in China predicted that the market scale of global furniture market will reach $556.1 billions. For most of the TFMA members who had bravely stepped forward to participate exhibitions, for instance, Orgatc Tokyo, AFF, MIFF, IWF, or Orgatec, had already tasted the opportunities of post-epidemic recovery. This year, many global buyers respond that they have not seen new products from various countries for a long time and are looking forward to finding more opportunities. Moreover, many of the exhibitors' ran out of their catalog and name cards in the first day of the exhibitions. Hence, We expected to have more members join us to participate the shows next year.

On the other hand, benefited from the development and lower cost of logistic, onlines furniture stores bring more choices and convenience for consumers. Statistics showed that, during 2017 to 2020, the market share of online sales in global furniture market has been increasing. Online channels become a new market driver worldwide. In the future, with the continuous development of e-commerce channels, logistics, and e-payment, online furniture market share is expected to have more expansion.

The report shows that the market scale of global furniture market will reach $650.7 billions, increased by $140.9 billion, with a growth rate of 27.6%, compared with 2020. Although the global epidemic in 2020 has caused a certain impact in the furniture industry, enterprises will have further integration that increase brand concentration, advantages of scales, and overall quality of industrial development.

Also, benefited from more popularity of the internet and payment technology, e-commerce has flourished that develops consumers' online shopping habits and behaviors. Due to the convenience of using images, videos and other media to display products online, and fast online payment, transaction efficiency has been greatly improved. According to the report, the revenue of the furniture e-commerce channel in the United States will reach $61.212 billions in 2025. Meanwhile, the scale in Europe will reach $51.964 billions. E-commerce channel will become a new highlight in global furniture market.

Source: TFMA

For domestic demand, the sales of imported furniture and other retail sectors increased by 14.16% YOY in the first half of 2020. It showed that, under the epidemic, more people increased their budget in healthy family lifestyle, driving growth for related industries. Since 2021, with the accessible vaccines, the world has developed a way of life that coexists with the virus. Entering the post-pandemic era, we found that a M-shaped consumer preference has shown in furniture market. Even though global market was suffered from the increased cost due to the shortage of labor and materials, the bantique furniture market has been growing. Thus, there still have huge potentials in luxurious bantique furniture sector.

On the other hand, environmental protection, energy saving, and carbon reduction are still the mainstreams in the market. Enterprises can achieve the goals through eco-friendly production, recyclable materials, or eco-materials, such as popinac or bamboo. Meanwhile, custom furniture service with AI virtual technology, multifunctional furnitures with composite structure for small spaces are ongoing trends. And, under the lower birth rate in East Asia, pet furniture become more popular. With its huge potentials, more furniture malls and exhibitions has launched pet segments.

In regards of export market, since 2016, the global furniture value had gradually recovered to $490 billions along with the world economy as of 2019. Since then, the market has been steady growth. In developed countries, citizens have stronger purchasing power that would make them pursue higher quality living spaces, generating a steady furniture demand from redecorating old houses or rental houses.

In developing countries, the increasing number of people in cities has led to the expansion of housing demand and the demands for furniture. Meanwhile, the rapid economic development of emerging market has increased residents' purchasing power. As a result, people have more capabilities and more desire to seek better living condition, which would drive continuous growth. Industry Consulting Expert in China predicted that the market scale of global furniture market will reach $556.1 billions. For most of the TFMA members who had bravely stepped forward to participate exhibitions, for instance, Orgatc Tokyo, AFF, MIFF, IWF, or Orgatec, had already tasted the opportunities of post-epidemic recovery. This year, many global buyers respond that they have not seen new products from various countries for a long time and are looking forward to finding more opportunities. Moreover, many of the exhibitors' ran out of their catalog and name cards in the first day of the exhibitions. Hence, We expected to have more members join us to participate the shows next year.

On the other hand, benefited from the development and lower cost of logistic, onlines furniture stores bring more choices and convenience for consumers. Statistics showed that, during 2017 to 2020, the market share of online sales in global furniture market has been increasing. Online channels become a new market driver worldwide. In the future, with the continuous development of e-commerce channels, logistics, and e-payment, online furniture market share is expected to have more expansion.

The report shows that the market scale of global furniture market will reach $650.7 billions, increased by $140.9 billion, with a growth rate of 27.6%, compared with 2020. Although the global epidemic in 2020 has caused a certain impact in the furniture industry, enterprises will have further integration that increase brand concentration, advantages of scales, and overall quality of industrial development.

Also, benefited from more popularity of the internet and payment technology, e-commerce has flourished that develops consumers' online shopping habits and behaviors. Due to the convenience of using images, videos and other media to display products online, and fast online payment, transaction efficiency has been greatly improved. According to the report, the revenue of the furniture e-commerce channel in the United States will reach $61.212 billions in 2025. Meanwhile, the scale in Europe will reach $51.964 billions. E-commerce channel will become a new highlight in global furniture market.

Source: TFMA

Joint- Chibin Sauce Chair

- 2023-01-05

Design Description Cheer bean’s origin is from the U.S. military assistance to Taiwan, they save the soybeans for the bean paste.so I hope to continue the concept of “cherish” to the design, let the chair frames which Huang Xiao-feng General Manager gets from her friend can get “reborn”. The chair frames themselves are Huang Xiao-feng General Manager gets from her friend, but because don't know how to use and idle in the ware house for many days, through this opportunity, re-design the chair frames to give those a new value. Construction Description Material Red oak, iron parts, universal adjustment legs Construction enon joints, wood screw fixation Designer :LI,JHEN-YU

"Smart Manufacturing from Anderson"

- 2023-01-05

In recent years, with the process of Industry 4.0 innovation, electrical component suppliers and software system suppliers of various integrated solutions have also followed the development trend. In addition to the covid-19 epidemic storm since 2020, the ever-changing market trends have catalyzed the transformation and upgrading of many industries. Smart manufacturing is one of the most comprehensive topics. How should smart manufacturing be done?

The perspective of Anderson, each industry has its production process and the supply/demand of upstream/downstream ecological chains are different, and it cannot be consistent for all. It is necessary to consider the possibility of phase in and reserve the possibility of future expansion and upgrading.

For the integration of smart manufacturing, the factory obtains the big data of the production process through the sensor on the machinery equipment, and makes a self-judgment with the front-end and back-end information processing software platforms to issue decision-making instructions, and sends them back through the system to processing equipment and automatic execution of programs, etc., the advanced processes and models of this type of function belong to a part of smart manufacturing.

.jpg) In other words, smart manufacturing is the various links in the production process of "smart machinery" can be integrated with related applications as long as IoT, cloud computing, big data, and AI artificial intelligence, and through network data streams, all devices can communicate with each other. The ultimate goal is to exchange information with each other in real time, and replace the traditional manufacturing process in real-time and quantified transparent management.

In the field of woodworking machinery, it is our direction to support “system furniture manufacturers” to introduce intelligent production. The first stage is to assist the industry to have "machinery and or so equipment to be more intelligence". In addition to the need to add more sensor components to the mechanical equipment itself, it is also necessary to optimize the human-machine interface of the machine operation so that it is not only to operate friendly, but more importantly, it can predict the data obtained from the sensor and temporarily store it locally. Directly compatible with external data processing software platform for real-time information exchange. After the industry possesses the basic elements of intelligent machinery, Anderson further thinks for customers and proposes a variety of automated upgrades before and after manufacturing integration solutions, including automated equipment such as robotic arms or Anderson self-developed crane type pick and place modules, etc., through integration the key to the combination of solutions is to optimize and improve the traditional manufacturing process during the hardware upgrade process, simplify the labor intensive level, and reduce the defect-rate caused by human errors in the original manufacturing process. In addition, through the network and the software data processing platform can also transmit the factory's manufacturing big data to mobile devices in real time, allowing management to grasp the production status more quickly.

In other words, smart manufacturing is the various links in the production process of "smart machinery" can be integrated with related applications as long as IoT, cloud computing, big data, and AI artificial intelligence, and through network data streams, all devices can communicate with each other. The ultimate goal is to exchange information with each other in real time, and replace the traditional manufacturing process in real-time and quantified transparent management.

In the field of woodworking machinery, it is our direction to support “system furniture manufacturers” to introduce intelligent production. The first stage is to assist the industry to have "machinery and or so equipment to be more intelligence". In addition to the need to add more sensor components to the mechanical equipment itself, it is also necessary to optimize the human-machine interface of the machine operation so that it is not only to operate friendly, but more importantly, it can predict the data obtained from the sensor and temporarily store it locally. Directly compatible with external data processing software platform for real-time information exchange. After the industry possesses the basic elements of intelligent machinery, Anderson further thinks for customers and proposes a variety of automated upgrades before and after manufacturing integration solutions, including automated equipment such as robotic arms or Anderson self-developed crane type pick and place modules, etc., through integration the key to the combination of solutions is to optimize and improve the traditional manufacturing process during the hardware upgrade process, simplify the labor intensive level, and reduce the defect-rate caused by human errors in the original manufacturing process. In addition, through the network and the software data processing platform can also transmit the factory's manufacturing big data to mobile devices in real time, allowing management to grasp the production status more quickly.

.jpg) In the process of moving towards the goal of evolution and upgrading of smart manufacturing, Anderson keeps improving and continues to look for collaborating manufacturers to jointly create diversified development possibilities in order to meet different customer needs. Therefore, Anderson has developed into not only a manufacturer of mechanical equipment, but also a developer and maintainer of software, and an integrator capable of cross-system integration technology.

Facing all new challenges, Anderson insists on innovation and continuous research and development, and diagnoses the most suitable solution for customers, so as to jointly achieve the vision expected by customers and Anderson.

In the process of moving towards the goal of evolution and upgrading of smart manufacturing, Anderson keeps improving and continues to look for collaborating manufacturers to jointly create diversified development possibilities in order to meet different customer needs. Therefore, Anderson has developed into not only a manufacturer of mechanical equipment, but also a developer and maintainer of software, and an integrator capable of cross-system integration technology.

Facing all new challenges, Anderson insists on innovation and continuous research and development, and diagnoses the most suitable solution for customers, so as to jointly achieve the vision expected by customers and Anderson.

WEINIG launches largest group-wide invest-ment program in the company's 117-year his-tory

- 2022-12-02

The WEINIG Group announced the launch of a comprehensive, large-scale investment project of more than 120 million euros on June 2, 2022. The Tauberbischofsheim site alone, the headquarters of the company with its 117-year track record of success, accounts for around 70 million euros of the total investment. The supervisory board of the WEINIG Group has approved a comprehensive, Group-wide investment program that will fundamentally reposition the Group and its headquarters in Tauberbischofsheim. In total, more than 120 million euros will be invested over the next 5 years. For the Voitsberg site in Austria, the production location of the subsidiary HOLZ-HER, 15 million euros have already been approved in advance and will be invested in assembly, production and logistics. The newly adopted program focuses mainly on the solid wood division of the mechanical engineering company. With 117 years of history at its main site in Tauberbischofsheim, the long-established company has set up a completely new site concept that will sustainably modernize production, significantly optimize delivery capability for customers and improve the working environment for its employees. This will included a new logistics center, a new manufacturing concept and new production facilities, as well as new exhibition and customer training rooms. Around 70 million euros will be invested in the infrastructure of the Tauberbischofsheim site alone. The supervisory board and the management board emphasized how the upcoming investments will position the company for the future. Dr. Thomas Bach, Chairman of the Supervisory Board of WEINIG AG, pointed out that it is part of the WEINIG DNA to see crises as opportunities, and that not least the Corona pandemic has provided room for conceptual work: “We looked for, identified and seized an opportunity in the crisis. As a result, we can confidently say today: WEINIG is fit for a successful future.” Chief Executive Officer Gregor Baumbusch explained that the wood processing industry is a growth sector that is getting an additional boost through sustainability and climate protection. The demand for machines and solutions that serve this market is correspondingly high and continues to rise. A further 40 million euros will therefore be invested in expanding the product portfolio. Mr. Baumbusch stated: “Today, we already have the broadest product portfolio of any supplier in the solid wood industry worldwide. Especially in the rapidly growing segment of timber construction, we will be able to offer our customers even better solutions from a single source, namely WEINIG, in the future.” Chief Technology Officer Dr. Georg Hanrath added that the future belongs to the triad of sustainable production, sustainable machines and the sustainable products manufactured on them. WEINIG is doing its part. Dr. Thomas Bach and Gregor Baumbusch expressed their thanks to the supervisory board and the shareholders, and in particular the works council and the employees of the WEINIG Group. He added that it is up to each and every one of us to ensure long-term economic success. The workforce is fully behind the planned measures and is looking forward to the improvements they will bring. Works council chairman Rainer Haag commented: “It is a joint project. Only if we all work together can we succeed. We have been discussing what that looks like over the past few months. The most important thing is that no jobs are cut. On the contrary, we will grow!” The machine builders from Tauberbischofsheim are prepared to tackle the future. Source from : WEINIG Group