Navigating the Future: CIFM / interzum guangzhou 2024 Explores Sustainable Solutions and Cutting-edge Trends

- 2024-04-01

CIFM / interzum guangzhou opened to the furniture production industry today at the Canton Fair Complex with much fanfare. The 2024 edition surpassed expectations with an expansive area of 180,000 square meters, hosting over 1,300 exhibitors from 31 countries and regions. Across the exhibition halls, visitors encountered a diverse array of cutting-edge products, technologies, and applications spanning furniture woodworking machinery, hardware, interiors, and more. With over 230 renowned international brands in attendance, CIFM / interzum guangzhou reinforced its status as a beacon of innovation and a catalyst for industry advancement.

.jpg) New Chapter

Amidst this vibrant atmosphere, industry luminaries convened on the first day to engage in forward-thinking discussions about development and future trends, underscoring the dynamic energy and vitality of the sector. The kick-off ceremony of the interzum guangzhou Award and VSIL Forum, followed by the prestigious award ceremony, celebrated the achievements of 20 outstanding enterprises. Among the esteemed winners were Aydın Tekstil, CHENYU TEXTILE, DewertOkin, DIC, eMoMo, HD Hardware, Henkel, INTERPRINT, Lien A, LINAK, Lion Rock, PRINTECH KR, PT ATEJA TRITUNGGAL, REHAU, Remacro, Renolit, Schattdecor, SIGE SPA, SIMALFA® and Tianan New Material.

New Chapter

Amidst this vibrant atmosphere, industry luminaries convened on the first day to engage in forward-thinking discussions about development and future trends, underscoring the dynamic energy and vitality of the sector. The kick-off ceremony of the interzum guangzhou Award and VSIL Forum, followed by the prestigious award ceremony, celebrated the achievements of 20 outstanding enterprises. Among the esteemed winners were Aydın Tekstil, CHENYU TEXTILE, DewertOkin, DIC, eMoMo, HD Hardware, Henkel, INTERPRINT, Lien A, LINAK, Lion Rock, PRINTECH KR, PT ATEJA TRITUNGGAL, REHAU, Remacro, Renolit, Schattdecor, SIGE SPA, SIMALFA® and Tianan New Material.

.jpg) The four-day event's significance was underscored by Matthias Pollmann, Vice President of Koelnmesse GmbH, who remarked, "Celebrating its 100th anniversary in 2024, Koelnmesse is the world’s top trade fair organiser for the areas of Living, Contract and Public Spaces, with a presence in key markets worldwide. In collaboration with the China Foreign Trade Centre Group, Ltd., CIFM / interzum guangzhou has evolved into the flagship exhibition for woodworking machinery, furniture manufacturing, and interiors in Asia.”

Michiel Kruse, Managing Director of Koelnmesse (Beijing) Co., Ltd., kicked off the interzum guangzhou Award & VSIL Forum, “With the keyword 'Surpass' for the 2024 edition, we aim to leverage this diverse platform to drive product and technological innovation through events like the interzum guangzhou Award and the 'Vitality of Sustainable Innovation to Life' (VSIL) Forum, empowering sustainable development in the furniture industry and guiding global stakeholders to new heights!"

The 2024 exhibition, supported by international industry associations, further solidified its prominence as a focal point for woodworking industry attention and market dynamics. Luigi De Vito, President of EUMABOIS, affirmed, "interzum guangzhou is certainly the spot of great interest for the woodworking business. It acts as an excellent indicator on market dynamics and it is a real springboard for innovation in a wide range of product categories."

Gathering of Innovations

Beyond the discussions and accolades, the exhibition halls brimmed with innovation from leading global brands, each showcasing their latest breakthroughs and achievements. Visitors were treated to a diverse array of products, from advanced woodworking machinery to innovative hardware solutions and sustainable materials.

In Hall 11.1, SCM Group dazzled with its high-precision CNC machining centers, while HSD from Italy showcased cutting-edge five-axis heads and electric spindles.

In Hall 12.1.The Taiwan Exhibitors are TaiChan, Lih Woei ,Innovator, Kuang Yung, Sk Global,Jun Shiau,CYWWM, Chang Tjer,City Tools,Blue Steel,Chia Lung,Kuoming Licom,Shen Ko,Weipinmech,NewsWin Media etc.

The four-day event's significance was underscored by Matthias Pollmann, Vice President of Koelnmesse GmbH, who remarked, "Celebrating its 100th anniversary in 2024, Koelnmesse is the world’s top trade fair organiser for the areas of Living, Contract and Public Spaces, with a presence in key markets worldwide. In collaboration with the China Foreign Trade Centre Group, Ltd., CIFM / interzum guangzhou has evolved into the flagship exhibition for woodworking machinery, furniture manufacturing, and interiors in Asia.”

Michiel Kruse, Managing Director of Koelnmesse (Beijing) Co., Ltd., kicked off the interzum guangzhou Award & VSIL Forum, “With the keyword 'Surpass' for the 2024 edition, we aim to leverage this diverse platform to drive product and technological innovation through events like the interzum guangzhou Award and the 'Vitality of Sustainable Innovation to Life' (VSIL) Forum, empowering sustainable development in the furniture industry and guiding global stakeholders to new heights!"

The 2024 exhibition, supported by international industry associations, further solidified its prominence as a focal point for woodworking industry attention and market dynamics. Luigi De Vito, President of EUMABOIS, affirmed, "interzum guangzhou is certainly the spot of great interest for the woodworking business. It acts as an excellent indicator on market dynamics and it is a real springboard for innovation in a wide range of product categories."

Gathering of Innovations

Beyond the discussions and accolades, the exhibition halls brimmed with innovation from leading global brands, each showcasing their latest breakthroughs and achievements. Visitors were treated to a diverse array of products, from advanced woodworking machinery to innovative hardware solutions and sustainable materials.

In Hall 11.1, SCM Group dazzled with its high-precision CNC machining centers, while HSD from Italy showcased cutting-edge five-axis heads and electric spindles.

In Hall 12.1.The Taiwan Exhibitors are TaiChan, Lih Woei ,Innovator, Kuang Yung, Sk Global,Jun Shiau,CYWWM, Chang Tjer,City Tools,Blue Steel,Chia Lung,Kuoming Licom,Shen Ko,Weipinmech,NewsWin Media etc.

.jpg) Meanwhile, in Hall 14.1, SIGE SPA presented its modular Hardware Home series, and Italiana Ferramenta unveiled its next-generation accessories solutions. Aydın Tekstil from Turkey showcased environmentally friendly textiles.

In Hall 15.1, Schattdecor unveiled its Fineflex series, merging modern design and eco-friendly materials. REHAU showcased its sleek RAUKANTEX Pigmento edgeband, offering seamless aesthetics for panel furniture. AICA debuted its customizable, eco-friendly home adhesives and films. DIC presented its famed HARTMANN ink and new moisture-resistant PUR products. DewertOkin exhibited an intelligent snoring control system with innovative sensor technology.

A Feast of Ideas

The exhibition will not only be a showcase of products but also a hub of ideas and discussions. The VSIL Forum, themed " Design Utopia - Global Furniture "Design & Supply Chain" Innovation," will bring together international designers and industry leaders from Schattdecor, Hettich and Domus Line to explore collaborative innovation between design and the supply chain.

Meanwhile, discussions on environmental sustainability and edge banding technology will highlight the industry's commitment to innovation and responsible practices. Awaiting participants from day two of the exhibition, the VSIL Forum will explore environmental protection and sustainability with experts from Europe, LINAK, SIMALFA®, and China’s Home Color Research Institute. They will discuss practical applications of sustainable development concepts in the home industry. The Boundless Design Forum, titled " Crafting the Perfect Edge - 2024 Panel Furniture Forum on Advanced Edgebanding Techniques" is poised to feature industry experts from IMA Schelling, Henkel, REHAU, and Renolit to examine international cutting-edge edge banding technology and solutions.

In parallel, partnering with the Asia Color Trend Book, the VSIL Gallery 2024 is set to captivate visitors with its visual delights, inviting them to immerse themselves in the themes of "Re-route" and "Coexistence." Through personalized color and material displays, the exhibition aims to inspire creativity and foresight, setting the stage for future aesthetic trends in the furniture industry.

Source: interzum guangzhou 2024

Meanwhile, in Hall 14.1, SIGE SPA presented its modular Hardware Home series, and Italiana Ferramenta unveiled its next-generation accessories solutions. Aydın Tekstil from Turkey showcased environmentally friendly textiles.

In Hall 15.1, Schattdecor unveiled its Fineflex series, merging modern design and eco-friendly materials. REHAU showcased its sleek RAUKANTEX Pigmento edgeband, offering seamless aesthetics for panel furniture. AICA debuted its customizable, eco-friendly home adhesives and films. DIC presented its famed HARTMANN ink and new moisture-resistant PUR products. DewertOkin exhibited an intelligent snoring control system with innovative sensor technology.

A Feast of Ideas

The exhibition will not only be a showcase of products but also a hub of ideas and discussions. The VSIL Forum, themed " Design Utopia - Global Furniture "Design & Supply Chain" Innovation," will bring together international designers and industry leaders from Schattdecor, Hettich and Domus Line to explore collaborative innovation between design and the supply chain.

Meanwhile, discussions on environmental sustainability and edge banding technology will highlight the industry's commitment to innovation and responsible practices. Awaiting participants from day two of the exhibition, the VSIL Forum will explore environmental protection and sustainability with experts from Europe, LINAK, SIMALFA®, and China’s Home Color Research Institute. They will discuss practical applications of sustainable development concepts in the home industry. The Boundless Design Forum, titled " Crafting the Perfect Edge - 2024 Panel Furniture Forum on Advanced Edgebanding Techniques" is poised to feature industry experts from IMA Schelling, Henkel, REHAU, and Renolit to examine international cutting-edge edge banding technology and solutions.

In parallel, partnering with the Asia Color Trend Book, the VSIL Gallery 2024 is set to captivate visitors with its visual delights, inviting them to immerse themselves in the themes of "Re-route" and "Coexistence." Through personalized color and material displays, the exhibition aims to inspire creativity and foresight, setting the stage for future aesthetic trends in the furniture industry.

Source: interzum guangzhou 2024

XYLEXPO 2024: JUST THREE MONTHS…

- 2024-02-29

…before the official opening of the 2024 edition, registrations keep flowing in from companies that decide to exhibit in Milan, in Halls 1 and 3 of Fieramilano Rho, at Xylexpo, the biennial international exhibition of wood and furniture industry technology scheduled next May 21 to 24. So far, just below 250 exhibitors will attend the event – back to its traditional calendar slot in May – presenting plants, solutions, products and technology that will provide plenty of international visitors with an upgrade on all process stages, from primary operation to the most innovative finishing. “Today more than ever, exhibitions accurately reflect the market health, and Xylexpo definitely offers a clear picture of the current situation of our industry, in Italy and globally”, said Dario Corbetta, exhibition director. “The record revenues of recent years have long been replaced by an inevitable reduction of orders. This situation was expected, but nevertheless, it caused many companies – despite high revenues supported by outstanding orders – to wait and see, to suspend investments in some activities, exhibitions on top of all. In recent weeks, many companies are reconsidering such decisions, but Xylexpo 2024 will inevitably have a different face”. At FieraMilano-Rho, many key players of technology will be attending, leveraging the opportunity to be under the spotlight in a challenging landscape, with many visitors expected from Italy and abroad. SCM, Felder, Naxing, KDT and several “famous” German and international brands have renovated their trust in an event that, don’t forget, is not just attractive for buyers, importers and international operators, but is located in one of the world’s most important markets for wood and furniture technology, with total demand exceeding one billion euro. Source: XYLEXPO 2024

INDIAWOOD 2024 - A Quarter Century of Excellence, Innovation and Global Dominance

- 2024-02-23

Bangalore, February 22, 2024 - The grand inauguration of INDIAWOOD 2024 today marks a significant milestone for the global woodworking and furniture manufacturing industry. Hosted at the Bangalore International Exhibition Centre from 22-26 February, INDIAWOOD 2024 underscores the industry's evolution and India's pivotal role in the global woodworking and furniture manufacturing market.

.jpg) Over the years, the event has established itself as the premier platform for innovation, collaboration, and growth in the woodworking and furniture manufacturing industry, not just in Asia but globally. The 2024 edition of INDIAWOOD sprawls over 75,000 square meters, showcasing over 950 exhibitors from more than 50 countries and will feature focused participation from Germany, Italy, France, Malaysia, USA and Taiwan. This year, the event is poised to welcome over 75,000 visitors, reflecting the industry's vibrant dynamics and the event's crucial role in shaping future trends. The exhibitors from Taiwan are CHI ING, GOODTEK, HOLYTEK, EXCELLENT,KUOMING,INNOVATOR,LEADERMAC, POWERMAX,SK GLOBAL,SANDERSON,LASERMAN,YOW CHERNG,TONG FONG,WENCHIH,RKE,NEWSWIN MEDIA,etc..

Over the years, the event has established itself as the premier platform for innovation, collaboration, and growth in the woodworking and furniture manufacturing industry, not just in Asia but globally. The 2024 edition of INDIAWOOD sprawls over 75,000 square meters, showcasing over 950 exhibitors from more than 50 countries and will feature focused participation from Germany, Italy, France, Malaysia, USA and Taiwan. This year, the event is poised to welcome over 75,000 visitors, reflecting the industry's vibrant dynamics and the event's crucial role in shaping future trends. The exhibitors from Taiwan are CHI ING, GOODTEK, HOLYTEK, EXCELLENT,KUOMING,INNOVATOR,LEADERMAC, POWERMAX,SK GLOBAL,SANDERSON,LASERMAN,YOW CHERNG,TONG FONG,WENCHIH,RKE,NEWSWIN MEDIA,etc..

.jpg) Furniture & Kitchen manufacturers, architects, interior designers, timber traders, saw millers, builders, contractors, hardware distributors, dealers from all over the world and neighbouring countries such as Nepal, Bhutan, Bangladesh, Sri Lanka, the Middle East participate in huge numbers at the event, reiterating its position as the melting pot for the “woodworking and furniture manufacturing” Industry.

Celebrating 25 Years of Excellence and Innovation

As INDIAWOOD approaches its 25th anniversary in 2025, the event has emerged as the cornerstone for the industry, driving development, sustainability, and growth. By providing a platform for businesses to expand their markets, forge international partnerships, and explore new opportunities, INDIAWOOD has played a pivotal role in shaping the economic landscape of the woodworking and furniture manufacturing sector. The event has contributed to job creation, skill development, and the promotion of exports, underpinning the industry's contribution to economic development and prosperity.

Furniture & Kitchen manufacturers, architects, interior designers, timber traders, saw millers, builders, contractors, hardware distributors, dealers from all over the world and neighbouring countries such as Nepal, Bhutan, Bangladesh, Sri Lanka, the Middle East participate in huge numbers at the event, reiterating its position as the melting pot for the “woodworking and furniture manufacturing” Industry.

Celebrating 25 Years of Excellence and Innovation

As INDIAWOOD approaches its 25th anniversary in 2025, the event has emerged as the cornerstone for the industry, driving development, sustainability, and growth. By providing a platform for businesses to expand their markets, forge international partnerships, and explore new opportunities, INDIAWOOD has played a pivotal role in shaping the economic landscape of the woodworking and furniture manufacturing sector. The event has contributed to job creation, skill development, and the promotion of exports, underpinning the industry's contribution to economic development and prosperity.

.jpg) From 2025 INDIAWOOD will alternate locations between Delhi and Bengaluru each year, ensuring a meticulously curated, focused, and internationally recognized platform to champion the industry's growth and global aspirations.

Woodworking Industry- The Backbone of India's Economic Landscape

The woodworking and furniture manufacturing sector is a vital component of India's booming economy. Contributing significantly to employment, manufacturing output, and export, the industry represents a blend of traditional craftsmanship and modern innovation. India's economic dominance, particularly in this sector, is a reflection of its capacity to blend high-skilled labour with cutting-edge technology, making it a global hub for furniture manufacturing and woodworking.

Sonia Prashar, Managing Director and Chairperson of the Board, NuernbergMesse India, stated, "As we inaugurate INDIAWOOD 2024, we are not just celebrating the present achievements but also laying the groundwork for the future. The woodworking and furniture manufacturing industry is at the cusp of a new era, driven by digital transformation and sustainability. Our vision is to propel India and INDIAWOOD to the forefront of this evolution, making it a global benchmark for innovation and excellence."

Sivakumar Venugopal, Member of the Management Board at NuernbergMesse India, added, "The 25th year of INDIAWOOD next year is a significant milestone that celebrates not just the longevity but also the impact of this event on the global stage. It is a reflection of our commitment towards fostering growth, innovation, and collaboration across continents. We are dedicated to showcasing the prowess of the Indian woodworking and furniture manufacturing industry to the world."

About INDIAWOOD:

INDIAWOOD 2024 showcase groundbreaking technologies and materials that are poised to redefine the future of woodworking. From high-performance adhesives and coatings to sustainable timber harvesting practices and eco-friendly finishes, INDIAWOOD will demonstrate the industry's commitment to sustainability and innovation. Visitors will also be able to explore the latest advancements in engineered wood products, such as cross-laminated timber (CLT), laminated veneer lumber (LVL), and glue-laminated timber (glulam).

From 2025 INDIAWOOD will alternate locations between Delhi and Bengaluru each year, ensuring a meticulously curated, focused, and internationally recognized platform to champion the industry's growth and global aspirations.

Woodworking Industry- The Backbone of India's Economic Landscape

The woodworking and furniture manufacturing sector is a vital component of India's booming economy. Contributing significantly to employment, manufacturing output, and export, the industry represents a blend of traditional craftsmanship and modern innovation. India's economic dominance, particularly in this sector, is a reflection of its capacity to blend high-skilled labour with cutting-edge technology, making it a global hub for furniture manufacturing and woodworking.

Sonia Prashar, Managing Director and Chairperson of the Board, NuernbergMesse India, stated, "As we inaugurate INDIAWOOD 2024, we are not just celebrating the present achievements but also laying the groundwork for the future. The woodworking and furniture manufacturing industry is at the cusp of a new era, driven by digital transformation and sustainability. Our vision is to propel India and INDIAWOOD to the forefront of this evolution, making it a global benchmark for innovation and excellence."

Sivakumar Venugopal, Member of the Management Board at NuernbergMesse India, added, "The 25th year of INDIAWOOD next year is a significant milestone that celebrates not just the longevity but also the impact of this event on the global stage. It is a reflection of our commitment towards fostering growth, innovation, and collaboration across continents. We are dedicated to showcasing the prowess of the Indian woodworking and furniture manufacturing industry to the world."

About INDIAWOOD:

INDIAWOOD 2024 showcase groundbreaking technologies and materials that are poised to redefine the future of woodworking. From high-performance adhesives and coatings to sustainable timber harvesting practices and eco-friendly finishes, INDIAWOOD will demonstrate the industry's commitment to sustainability and innovation. Visitors will also be able to explore the latest advancements in engineered wood products, such as cross-laminated timber (CLT), laminated veneer lumber (LVL), and glue-laminated timber (glulam).

.jpg) Spotlight will also be on the integration of digital technologies into woodworking processes, including CNC machining, robotics, smart edge banding solutions for seamless finishing, and laser cutting systems for precise cutting and engraving.

INDIA MATTRESSTECH + UPHOLSTERY SUPPLIES EXPO (IME), held concurrently will have on display the latest technology for mattress production machinery and supplies, mattress finishing machinery and supplies, production tools and equipment, upholstery production technology, bed systems, new materials etc.

The third edition of 'Wood+ in Architecture and Design (WAD)', one day conference, to be held on the 24th of February will bring together Architects, Structural Engineers, Designers and Mass-Timber manufacturers to explore through panel discussions, expert presentations, and interesting case studies the application of wood as a construction material. www.w-a-d.in.

Newest launch SURFACE IN MOTION, one day conference on decorative surfaces for wood-based materials, will be held on 23rd February; where top experts from Europe and India will present topics such as decor design, the latest surface technologies, production processes and trends.

Spotlight will also be on the integration of digital technologies into woodworking processes, including CNC machining, robotics, smart edge banding solutions for seamless finishing, and laser cutting systems for precise cutting and engraving.

INDIA MATTRESSTECH + UPHOLSTERY SUPPLIES EXPO (IME), held concurrently will have on display the latest technology for mattress production machinery and supplies, mattress finishing machinery and supplies, production tools and equipment, upholstery production technology, bed systems, new materials etc.

The third edition of 'Wood+ in Architecture and Design (WAD)', one day conference, to be held on the 24th of February will bring together Architects, Structural Engineers, Designers and Mass-Timber manufacturers to explore through panel discussions, expert presentations, and interesting case studies the application of wood as a construction material. www.w-a-d.in.

Newest launch SURFACE IN MOTION, one day conference on decorative surfaces for wood-based materials, will be held on 23rd February; where top experts from Europe and India will present topics such as decor design, the latest surface technologies, production processes and trends.

.jpg) Source: INDIA WOOD 2024

Source: INDIA WOOD 2024

SCM at DACH+HOLZ International 2024: expertise and innovation for the timber construction industry

- 2024-02-16

The stars of the SCM stand will be the OIKOS XS cnc machining centre and the new Maestro active beam&wall HMI software.

Stuttgart, 5-8 March 2024

Hall 10, stand 421

SCM returns to DACH+HOLZ International with state-of-the-art innovations and a rich programme of technical demonstrations and insights dedicated to the timber construction industry.

The result of continuous investment in research and development and the Italian Group's constant focus on the latest requirements of the green building industry will be on show in an exhibition space dedicated to high technology and the latest trends in the sector (Hall 10, Stand 421).

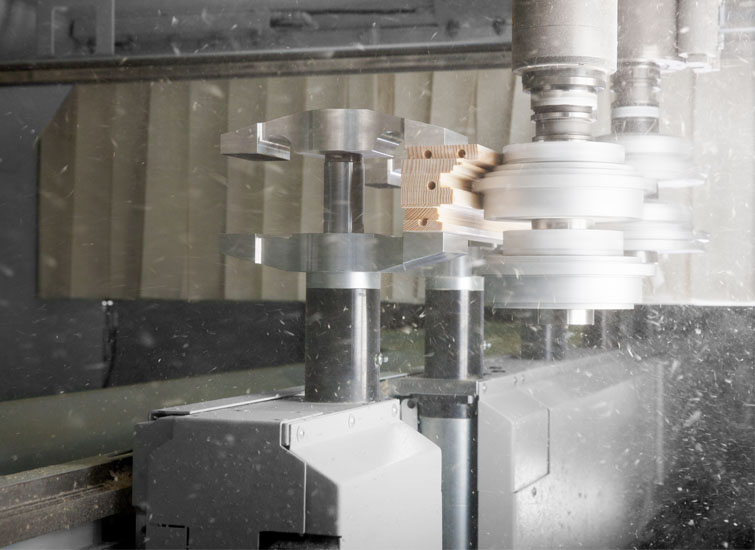

Prominent on the stand will be the OIKOS XS cnc machining centre, which visitors to the fair will be able to see in action in all its potential, thanks to demos dedicated to the production of specific structural elements: different types of timber frame walls, roof portions, structural beams and elements with X-fix connection.

Other demos will be dedicated to software, to experience live the advantages offered by the new Maestro active beam&wall HMI, transversal to all models of the Oikos and Area ranges of CNC machining centres for timber construction.

The Stuttgart event will also be an opportunity to take a closer look at the entire SCM range for the timber construction industry: in a cosy SCM Arena, presentations will be given on the other new additions to the wide range of cnc solutions such as OIKOS XL+ and DMC SYSTEM XL, automatic sanding-calibrating machine, as well as discovering the latest trends together with green building experts.

TECHNOLOGY HIGHLIGHTS

OIKOS XS: speed of execution and high configurability

OIKOS XS is the most versatile model in the Oikos range, cnc machining centre for timber construction ideal for companies looking for high speed and precision combined with a small footprint and low cost.

It is suitable for the production of straight beams, prefabricated walls, trusses, roofs and blockhouses, i.e. structural elements requiring both very fast operations such as cutting, and more complex operations such as drilling, routing, dovetails and slots for hardware, on pieces that can have a maximum length of 16 metres, a maximum width of 450 mm and a maximum thickness of 240 mm.

The speed of execution is one of the main advantages, because the work piece feed rates can increase up to 3 m/sec. Furthermore, combined movements of the operating units cut down unproductive time due to axis repositioning.

OIKOS XS enables the coverage of the work piece 6 faces. Several operating units strategically positioned within the work area, resulting in a high degree of configurability to meet every specific customer need. Another plus is the innovative 4+1 axes revolver unit with differentiated speeds for each tool which allows for a unique finish.

The machine also stands out for its machining precision, which is achieved by extremely stiff clamping system for work piece feed, horizontal and vertical pressure rollers located close to the work area, a dynamic work piece support system active during processing and a laser probe to realize precise dovetails.

OIKOS XS is the most versatile model in the Oikos range, cnc machining centre for timber construction ideal for companies looking for high speed and precision combined with a small footprint and low cost.

It is suitable for the production of straight beams, prefabricated walls, trusses, roofs and blockhouses, i.e. structural elements requiring both very fast operations such as cutting, and more complex operations such as drilling, routing, dovetails and slots for hardware, on pieces that can have a maximum length of 16 metres, a maximum width of 450 mm and a maximum thickness of 240 mm.

The speed of execution is one of the main advantages, because the work piece feed rates can increase up to 3 m/sec. Furthermore, combined movements of the operating units cut down unproductive time due to axis repositioning.

OIKOS XS enables the coverage of the work piece 6 faces. Several operating units strategically positioned within the work area, resulting in a high degree of configurability to meet every specific customer need. Another plus is the innovative 4+1 axes revolver unit with differentiated speeds for each tool which allows for a unique finish.

The machine also stands out for its machining precision, which is achieved by extremely stiff clamping system for work piece feed, horizontal and vertical pressure rollers located close to the work area, a dynamic work piece support system active during processing and a laser probe to realize precise dovetails.

New HMI Maestro active beam&wall for quick and easy all-round control

Maestro active beam&wall is the new human-machine interface software dedicated to CNC machining centres for timber construction, which offers numerous functions in a simple and fast way:

Multi-project: it allows the production of elements of the same section but which are part of different projects to be optimised on the same raw bars, in order to minimise material waste. The optimisation process is fully automatic.

3D visualisation: possibility of exploring the workpiece and taking measurements. On the 3D element, the tool paths of the machining units are traced in real-time.

Complete job management: management of routine maintenance, machine alarms, work shifts, printing of labels and creation of production reports... these are just some of the functions that the software makes available to the customer.

Advanced user management: different levels of authorisation can be enabled for each machine operator depending on their capabilities, in order to protect the machining centre from incorrect manipulation.

The new version of the HMI software is characterised by a totally renewed graphic interface aligned with that of the latest generation of software. Maestro active beam&wall is based on Maestro active, the HMI software adopted by the entire SCM Group for complete job order management.

Last but not least, the presence of the new eye-M top plus operator console compatible with all models in the Area and Oikos ranges. On the same console, upon request, the Maestro beam&wall programming software can also be installed, closely connected to the HMI software. The possibility of using Maestro beam&wall both on a PC in the office and on the operator console, i.e. directly on the machine even for the programming phase, is an important advantage for companies that reckon on flexibility of use to increase their productivity.

OTHER NEW PRODUCTS PRESENTED IN DIGITAL MODE

OIKOS XL+ for great eco-sustainable challenges

OIKOS XL+ is the new CNC machining centre for the production of columns and structural beams with a max. cross-section of 1250x610 mm. This solution has inherited all characteristics of OIKOS XL, a machining centre chosen by leading companies both in Europe and North America, amplifying all its advantages, thanks to the implementation of a second independent machining unit with a 1150 mm diameter saw blade.

New HMI Maestro active beam&wall for quick and easy all-round control

Maestro active beam&wall is the new human-machine interface software dedicated to CNC machining centres for timber construction, which offers numerous functions in a simple and fast way:

Multi-project: it allows the production of elements of the same section but which are part of different projects to be optimised on the same raw bars, in order to minimise material waste. The optimisation process is fully automatic.

3D visualisation: possibility of exploring the workpiece and taking measurements. On the 3D element, the tool paths of the machining units are traced in real-time.

Complete job management: management of routine maintenance, machine alarms, work shifts, printing of labels and creation of production reports... these are just some of the functions that the software makes available to the customer.

Advanced user management: different levels of authorisation can be enabled for each machine operator depending on their capabilities, in order to protect the machining centre from incorrect manipulation.

The new version of the HMI software is characterised by a totally renewed graphic interface aligned with that of the latest generation of software. Maestro active beam&wall is based on Maestro active, the HMI software adopted by the entire SCM Group for complete job order management.

Last but not least, the presence of the new eye-M top plus operator console compatible with all models in the Area and Oikos ranges. On the same console, upon request, the Maestro beam&wall programming software can also be installed, closely connected to the HMI software. The possibility of using Maestro beam&wall both on a PC in the office and on the operator console, i.e. directly on the machine even for the programming phase, is an important advantage for companies that reckon on flexibility of use to increase their productivity.

OTHER NEW PRODUCTS PRESENTED IN DIGITAL MODE

OIKOS XL+ for great eco-sustainable challenges

OIKOS XL+ is the new CNC machining centre for the production of columns and structural beams with a max. cross-section of 1250x610 mm. This solution has inherited all characteristics of OIKOS XL, a machining centre chosen by leading companies both in Europe and North America, amplifying all its advantages, thanks to the implementation of a second independent machining unit with a 1150 mm diameter saw blade.

In line with the increased expansion of multi-storey wooden buildings globally, OIKOS XL+ has been designed to overcome even the most complex challenges. The robust and adequately sized structure of the machine means very heavy elements of up to 4 tons can be processed, as well as very hard materials.

Flexibility is another key point, in fact any operation on any side of the work piece can be performed with no need of repositioning, thanks to the innovative 6-axis architecture of the main machining unit. Productivity and precision are other primary requirements that are the basis of this model.

The second 5-axis saw blade unit allows a blade radius of an impressive 400 mm. Furthermore, the use of a saw blade rather than a chainsaw aggregate means to work faster and achieve a better quality.

Another advantage is the ability to execute cuts from bars with a maximum thickness of 610 mm. Decisive is the machining strategy behind the OIKOS XL+, which combines the second saw blade unit with the main machining unit that has a 740 mm diameter saw blade.

In line with the increased expansion of multi-storey wooden buildings globally, OIKOS XL+ has been designed to overcome even the most complex challenges. The robust and adequately sized structure of the machine means very heavy elements of up to 4 tons can be processed, as well as very hard materials.

Flexibility is another key point, in fact any operation on any side of the work piece can be performed with no need of repositioning, thanks to the innovative 6-axis architecture of the main machining unit. Productivity and precision are other primary requirements that are the basis of this model.

The second 5-axis saw blade unit allows a blade radius of an impressive 400 mm. Furthermore, the use of a saw blade rather than a chainsaw aggregate means to work faster and achieve a better quality.

Another advantage is the ability to execute cuts from bars with a maximum thickness of 610 mm. Decisive is the machining strategy behind the OIKOS XL+, which combines the second saw blade unit with the main machining unit that has a 740 mm diameter saw blade.

DMC SYSTEM XL: built bigger to work harder

Two years after the launch of DMC SYSTEM XL, automatic sanding-calibrating machine for timber construction sector, with its firsts three modules (roller, pad and crossbelt units), the machine has been further enriched with new units that enable to process both top and bottom face of CLT panels up to 3.700 mm wide and 500 mm thick.

New features presented at Dach+Holz 2024 are: bottom roller unit, top/bottom pad unit and “piggyback” crossbelt unit, modules that can be fully combined and integrated with each other according to the customer's production requirements, by offering very high configuration versatility (a distinctive plus of DMC SYSTEM XL) and unification of components and common parts to optimize operating costs.

The solid steel structure is conceived to last long and withstand the most intense machining, by granting zero-vibration. Furthermore, the automatic sanding-calibrating machine has been developed to make the operator's maintenance work easy, fast and always safe.

Energy saving is a key issue: the machine has been specifically engineered with an optimized design and technological solution for minimum compressed air consumption.

Even this solution, as well as all SCM sanding technological offer, is aimed at improving the surface finishing and increase the value of the finished product. Reflecting the latest market trends in having visible CLT walls and a product that is as natural as possible (without resorting to additional surface treatments).

Source: SCM Group

DMC SYSTEM XL: built bigger to work harder

Two years after the launch of DMC SYSTEM XL, automatic sanding-calibrating machine for timber construction sector, with its firsts three modules (roller, pad and crossbelt units), the machine has been further enriched with new units that enable to process both top and bottom face of CLT panels up to 3.700 mm wide and 500 mm thick.

New features presented at Dach+Holz 2024 are: bottom roller unit, top/bottom pad unit and “piggyback” crossbelt unit, modules that can be fully combined and integrated with each other according to the customer's production requirements, by offering very high configuration versatility (a distinctive plus of DMC SYSTEM XL) and unification of components and common parts to optimize operating costs.

The solid steel structure is conceived to last long and withstand the most intense machining, by granting zero-vibration. Furthermore, the automatic sanding-calibrating machine has been developed to make the operator's maintenance work easy, fast and always safe.

Energy saving is a key issue: the machine has been specifically engineered with an optimized design and technological solution for minimum compressed air consumption.

Even this solution, as well as all SCM sanding technological offer, is aimed at improving the surface finishing and increase the value of the finished product. Reflecting the latest market trends in having visible CLT walls and a product that is as natural as possible (without resorting to additional surface treatments).

Source: SCM Group

HOMAG Technology Days 2024

- 2024-02-15

New solutions, new possibilities… in our showrooms throughout Germany

At HOMAG Technology Days, visitors can discover exclusive solutions in the areas of panel dividing, CNC, edge processing, digital solutions, automation and more, first hand at HOMAG locations throughout Germany. In addition to machines, digital products and production methods, the main focus of these special events is interaction and dialog with YOU! Together, we will immerse ourselves in the latest woodworking technologies - with the right focus on your unique needs.

Technology Days at a glance:

- 12.-14. March – Focus: Sawing, Cutting and Panel Dividing in Holzbronn

- 10.-12. April – Focus: CNC and Edge Processing in Herzebrock

- 16.-17. April – Focus: Building Component Manufacturing in Schopfloch

- 14.-15. Mai – Focus: Edge Processing and Automation in Schopfloch

Focus: Sawing, Cutting and Panel Dividing

12.-14. March 2024, Holzbronn

-

In Holzbronn, visitors will experience state-of-the-art technologies for perfect panel dividing, from material handling to advanced production. The spectrum ranges from precise cuts to intelligent material utilization.

Our highlights:

- Perfect entry-level solutions: The SAWTEQ S-200 and the updated SAWTEQ S-300 flexTec robotic saw, fed by STORETEQ F-100 single-axis feeder

- NEW: Flexible nesting with the CENTATEQ N-210, combined with the STORETEQ P-300 storage system (with new woodStore features), and the new generation of SAWTEQ S-300 as a “storage-saw-nesting” cell concept

-

The extended opening hours are another special feature. They offer all visitors the ideal opportunity to talk shop and enjoy a relaxed exchange between experts, during the workday or at the end the day after their work is done.

Opening hours:

- Tuesday, 12.03.2024: 11:00 – 20:00

- Wednesday, 13.03.2024: 11:00 – 20:00

- Thursday, 14.03.2024: 09:00 – 17:00

-

Focus: CNC and Edge Processing

-

10.-12. April 2024, Herzebrock

-

.jpg)

-

Visitors to Herzebrock will discover innovative CNC and edge processing solutions for the workshop. HOMAG will show visitors new perspectives and various options for optimizing work processes, from digital workflows and smart machine integration concepts to automated production solutions. And of course, individual machines for your individual needs.

Our highlights:

- NEW: EDGETEQ S-200 with new, top-mounted gluing unit for PUR or EVA

- NEW: EDGETEQ S-380 with the new, material friendly LOOPTEQ O-400 return conveyor

- DRILLTEQ V-310 with automatic material return and new integrated turning function

- Experience over 1,600 m² of state-of-the-art technology in one compact location – complemented by suitable automation solutions and smart digital helpers

-

Focus: Building Component Manufacturing (Windows, Stairs, Doors)

16.-17. April 2024, Schopfloch

-

From idea to production: During the Technology Days with a focus on component production in Schopfloch, visitors will discover technologies that facilitate and optimize the production of high-quality windows, stairs and doors.

Our Highlights:

- Celebrate 25 years of HOMAG window production technology!

- See the CENTATEQ S-800/S-900 for automated window production, bar processing and block frame production – from entry-level to customized system concepts

- Whether you’re producing staircases, furniture, windows, doors or interior fittings – with

- the CNC processing centers of our CENTATEQ series, you have all the tools you need

- Informative specialist presentations: From experts for experts

- Personal exchange with other industry experts

-

Focus: Edge Processing and Automation

14.-15. May 2024, Schopfloch

-

Perfect edges for perfect results. At the Technology Days with a focus on edge processing and automation in Schopfloch, HOMAG is focusing on outstanding edge processing with the right automation solutions - from the entry-level versions to fully automatic part circulation.

Our Highlights:

- NEW: EDGETEQ S-200 with new, top-mounted gluing unit for PUR or EVA

- NEW: EDGETEQ S-500 with the new, material friendly LOOPTEQ O-400 return conveyor

- Edge cells from small to large: From the EDGETEQ S-380 with LOOPTEQ O-300 return conveyor, to the EDGETEQ S-500 with LOOPTEQ O-600, up to the EDGETEQ S-800 with LOOPTEQ C-500 edge circulation unit

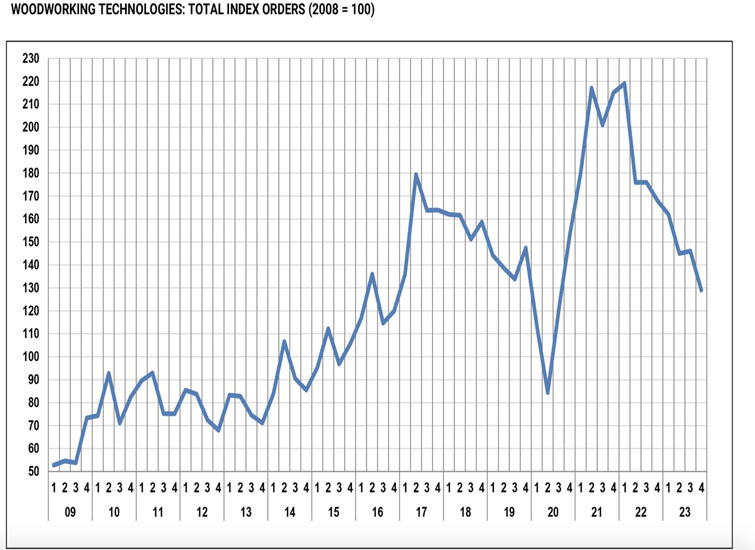

WOODWORKING TECHNOLOGY: FOURTH QUARTER STILL DECLINING

- 2024-02-14

After the booming growth of recent years, another negative quarter is expected for the processing industry of wood and wood-based materials. This trend is emerging from the traditional quarterly survey carried out by the Studies Office of Acimall, the association of Italian woodworking and furniture technology manufacturers, which continues to show a falling trend for orders, in line with the previous quarters. The October-December 2023 figures show an overall reduction of orders by 23.6 percent compared to the same period of 2022, resulting from the combination of incoming orders from abroad (minus 6.3 percent) and a sharp decline in domestic demand (minus 48.1 percent), largely due to a wait-and-see attitude encouraged by the expected implementation of the new “Industria 5.0” measures. So, the back-to-normal trend after the exceptional results of 2020-2022 has combined with the wait for the new decree, whose details are being delayed, inevitably causing a negative impact on investment decisions for instrumental goods. However, the wood and furniture technology industry can still rely on a significant order backlog of 4.5 months, having saved for a rainy day in the past years when demand was high. Prices are rallying, up by 1.9 percent since January 2023. According to the quality survey, 55 percent of the interviewed companies expect substantial stability in production, while 25 percent predict an increase and 20 percent further reduction. 10 percent of interviewed companies expect increasing employment, while 70 percent indicate substantial stability and 20 percent fear a reduction. Available stocks are stable according to 50 percent of the interviewees, increasing for 20 percent and decreasing for 30 percent. Let’s take a look at the results of the forecast survey: on the domestic market, the figures processed by the Studies Office of Acimall reveal that 50 percent of the sample expect stability, 15 percent increasing orders and 35 percent a reduction. Expectations are more balance for the foreign markets: 40 percent said the trend will remain stable, while things will get worse according to 35 percent. The remaining 25 percent expect an increase in orders. “We can only repeat what we have been saying for months”, said Acimall Director Dario Corbetta. “In recent times, our industry has benefited from a very positive situation that could not last forever, and now we have to face a return to pre-Covid levels”. This situation must not scare Italian companies, as they are perfectly fit to face any situation, as the history of our industry shows. For sure, the definition of details of the “Industry 5.0” decree and its tangible consequences might have a strong impact on the trends emerging from our data, and this is the direction where the entire community of mechanical engineering is heading”. Source:ACIMALL