Leadermac 50th anniversary

- 2021-10-01

The time-honored "Leadermac" has been deeply involved in the woodworking machinery industry in Taiwan. Leadermac Machinery company now is the world’s second largest manufacturer of four side moulder. This year celebrates its 50th anniversary. The two generations relay of the Chang family in 50 years has completed the proud, "Taiwan number one. At this important moment, the editorial team interviewed Michael Chang, president of Leadermac, and listened to him elaborate on the company’s growth and future vision and plans.

.jpg) Leadermac important process monument

Established in 1972, Leadermac has gone through 50 years of testing, from the traditional woodworking machinery manufacturing to the largest professional manufacturer of four side planers in Taiwan and the second largest in the world. Chairman Michael Chang expressed its important turning point. In the successful decentralized market: Because the early market was too concentrated in the Asian and Southeast Asian markets, in order to enter the European and American markets, LEADERMAC brand was established in 1994, and the CE certification was simultaneously applied for, and at the same time, the mechanical and electrical specifications that comply with the European regulations were set up to European specifications to enter new markets. In 1995, Leadermac participated in the LIGNA Hannover Woodworking Machinery Exhibition in Germany for the first time. (LIGNA is the world’s largest international woodworking machinery exhibition held every two years), and successively find European agents, such as Denmark, Sweden, Finland and other countries. This is an important turning point for Leadermac to enter the European and American markets. With local agents in Europe, Leadermac successfully explored the European market.

In 2013, it started to move towards the goal of automation from a single machine to an automated .the year 2020, the automatic production equipment for the solid wood production line was released. It is an important process of the automation of Leadermac in recent years, and it is also an intelligent production. Set rules.

Leadermac important process monument

Established in 1972, Leadermac has gone through 50 years of testing, from the traditional woodworking machinery manufacturing to the largest professional manufacturer of four side planers in Taiwan and the second largest in the world. Chairman Michael Chang expressed its important turning point. In the successful decentralized market: Because the early market was too concentrated in the Asian and Southeast Asian markets, in order to enter the European and American markets, LEADERMAC brand was established in 1994, and the CE certification was simultaneously applied for, and at the same time, the mechanical and electrical specifications that comply with the European regulations were set up to European specifications to enter new markets. In 1995, Leadermac participated in the LIGNA Hannover Woodworking Machinery Exhibition in Germany for the first time. (LIGNA is the world’s largest international woodworking machinery exhibition held every two years), and successively find European agents, such as Denmark, Sweden, Finland and other countries. This is an important turning point for Leadermac to enter the European and American markets. With local agents in Europe, Leadermac successfully explored the European market.

In 2013, it started to move towards the goal of automation from a single machine to an automated .the year 2020, the automatic production equipment for the solid wood production line was released. It is an important process of the automation of Leadermac in recent years, and it is also an intelligent production. Set rules.

.jpg) Inheritance and succession

Michael returned to Taiwan from Canada in 1992 and joined Leadermac. He started from the grassroots level and experienced production, management and business departments. Until 1999, he served as the company's general manager and entered the company's core business. Michael is gratefully said: "The most important thing is to thank my father for his support, so that I can carry out drastically, both internally and externally, so that I have the power to change, Michael thanked his father for his support, allowing him to give full play to his strengths and contribute to the company.

Inheritance and succession

Michael returned to Taiwan from Canada in 1992 and joined Leadermac. He started from the grassroots level and experienced production, management and business departments. Until 1999, he served as the company's general manager and entered the company's core business. Michael is gratefully said: "The most important thing is to thank my father for his support, so that I can carry out drastically, both internally and externally, so that I have the power to change, Michael thanked his father for his support, allowing him to give full play to his strengths and contribute to the company.

.jpg) At that time, the company's product sales were 90% concentrated in China and Southeast Asia, but after experiencing the economic storm in Asia in 1997, the team realized the importance of diversifying risks, so it set the goal of diversifying the market to avoid putting eggs in the same basket

Regarding entering the European and American markets, Michael said that this is a long-term journey. It is necessary to continuously participate in European and American international exhibitions step by step. The preparation process is like participating in the Olympic Games. Exhibit equipment not only meets the requirements of European regulations, but also respects and avoids patent protection. The expansion of the European and American markets adopts the strategy of Country surrounds the city, such as selling from small countries in Southern and Western Europe, and finally Enter the core group, such as Germany, France, Austria and other countries.

At that time, the company's product sales were 90% concentrated in China and Southeast Asia, but after experiencing the economic storm in Asia in 1997, the team realized the importance of diversifying risks, so it set the goal of diversifying the market to avoid putting eggs in the same basket

Regarding entering the European and American markets, Michael said that this is a long-term journey. It is necessary to continuously participate in European and American international exhibitions step by step. The preparation process is like participating in the Olympic Games. Exhibit equipment not only meets the requirements of European regulations, but also respects and avoids patent protection. The expansion of the European and American markets adopts the strategy of Country surrounds the city, such as selling from small countries in Southern and Western Europe, and finally Enter the core group, such as Germany, France, Austria and other countries.

.jpg) Challenges facing Taiwan in the post-epidemic era

Refer to the impact of the new crown pneumonia COVID 19 on Taiwan’s woodworking machinery, Michael analyzed that because Taiwan’s control of the epidemic is better than other countries this time, the Sino-US trade war has surfaced at this time, and the semiconductor industry has stabilized its leading position. The popularity of Taiwan has jumped up. At this moment, the world is relatively repulsive of Chinese products, and many foreign orders have been transferred to Taiwan and other Asian countries. Take Leademac as an example. The biggest profit is the US market, plus tariff preferences, which is the best period in history

However, internal obstacles, including rising source materials, exchange rate fluctuations, soaring freight rates, and the shortage of AI talents in Taiwan’s manufacturing industry, have caused various difficulties in the internal operations of Taiwan’s manufacturing industry and have also tested the wisdom of leaders.

About Future

Regarding the future, Michael said that continuous positive thinking and continuous change are like the company's motto and vision: "The only constant in life is change, the pursuit of excellence and the goal of a happy company." To achieve a happy company, you must satisfied customers, because when the customer is satisfied, the company will have continuous orders, and gain profits for the R&D promotion of various departments of the company, especially in terms of AI and IOT overflow and employee benefits, so as to continue to promote the happy enterprise and the industry. 4.0 forward. However, compared with large foreign companies, Taiwan’s happy companies are not necessarily to be large. However, in the future, the weapon that determines the success or failure of the company is to invest in AI, otherwise the road ahead will be very hard. This is the way to go.

Photos by Leadermac

By NewsWin

Challenges facing Taiwan in the post-epidemic era

Refer to the impact of the new crown pneumonia COVID 19 on Taiwan’s woodworking machinery, Michael analyzed that because Taiwan’s control of the epidemic is better than other countries this time, the Sino-US trade war has surfaced at this time, and the semiconductor industry has stabilized its leading position. The popularity of Taiwan has jumped up. At this moment, the world is relatively repulsive of Chinese products, and many foreign orders have been transferred to Taiwan and other Asian countries. Take Leademac as an example. The biggest profit is the US market, plus tariff preferences, which is the best period in history

However, internal obstacles, including rising source materials, exchange rate fluctuations, soaring freight rates, and the shortage of AI talents in Taiwan’s manufacturing industry, have caused various difficulties in the internal operations of Taiwan’s manufacturing industry and have also tested the wisdom of leaders.

About Future

Regarding the future, Michael said that continuous positive thinking and continuous change are like the company's motto and vision: "The only constant in life is change, the pursuit of excellence and the goal of a happy company." To achieve a happy company, you must satisfied customers, because when the customer is satisfied, the company will have continuous orders, and gain profits for the R&D promotion of various departments of the company, especially in terms of AI and IOT overflow and employee benefits, so as to continue to promote the happy enterprise and the industry. 4.0 forward. However, compared with large foreign companies, Taiwan’s happy companies are not necessarily to be large. However, in the future, the weapon that determines the success or failure of the company is to invest in AI, otherwise the road ahead will be very hard. This is the way to go.

Photos by Leadermac

By NewsWin

Greeting from Mr. Michael Chang

- 2021-09-30

Congratulations on the launch of the "Woodworking Machinery" magazine! Taiwan woodworking machinery industry has been in the industry for decades, and its total export quality ranks second only to Germany, China, and Italy, and its global export ranks fourth. More than 80% of Taiwan’s woodworking machinery is for export. There are nearly 300 manufacturers, and more than 80% of the manufacturers are concentrated in the central region, mainly in Fengyuan, Shengang and other regions. There are close upstream and downstream supply chains clustered, and manufacturers can be in a short period of time. Obtaining the mutual support and supply of the required parts is the greatest advantage and strength of the development of Taiwan's woodworking machinery. The chairman of Taiwan Woodworking Machinery Association Mr. Michael Chang

CIFM / interzum guangzhou paints new chapter in 2022 with focus on sustainable innovation

- 2021-09-29

China’s ability to control the coronavirus pandemic and subsequent emergence as an even stronger economy has attracted global attention, including major furniture companies. As Asia’s flagship furniture manufacturing exhibition, CIFM / interzum guangzhou, to take place in conjunction with the China International Furniture Fair from 28 - 31 March 2022, is in a favourable position to leverage the growth. According to statistics, China's furniture manufacturing output reached 520 million units in the first half of 2021, a year-on-year increase of 30.1 per cent. In terms of exports, the cumulative value of the country's furniture and parts exports as of July hit US$40.926 billion, a year-on-year increase of 47.20 per cent. Among them, furniture exports to Germany in the first half of the year increased by 45 per cent, replacing Poland as Germany's most important furniture supplying country. International platform for global trade China is experiencing a good momentum as a continuously growing economy. Under the country’s dual circulation economic policy powered by domestic consumption, the Pearl River Delta region’s concentration of custom furniture makers and reputation for producing ‘everything under the sun’ makes it particularly appealing for global players to mine the China market. As an affluent society, the expansion of domestic demand further drives lucrative industry opportunities, digitalization and new materials to emerge at scale. CIFM / interzum guangzhou 2022 will take up 340,000 square meters in floor space, and is expected to feature over 2,000 well-known companies from around the world. Some 200,000 visitors are also slated to source at the event. Backed by a wealth of global resources, the exhibition covers the entire industry vertical. Exhibit categories include: hardware accessories and components; interior decoration materials and accessories; machinery, auxiliary materials and accessories for upholstered furniture; wood products and panels; adhesives, coatings and other chemical raw materials; and machinery, accessories and equipment for woodworking furniture production. International companies have been showing active interest in CIFM / interzum guangzhou to open up the business opportunities and gain a foothold in the immense China as well as Asian market. At present, a number of international giants have confirmed their participation, including: Homag, IMA, Nanxing, KDT, Paolino Bacci, Freud, SANDAR, HOLD, Leitz, Lianrou, Yuantian, Hengchang, Hengye, Kehua, Schattdecor, REHAU, LG, Hyundai, Kronospan, Henkel, LINAK, Dilong, Taiqiang, Yaodonghua, Jiashijia, SINODECOR, Yongwei, Huamei, Zhuokai, KINNAY, Liwang, Zhaogang, DREAM LEADER, Tianye, Anran, DTC, SH-ABC, ADAMS, UNIHOPPER, Jusen, UNION STAR, OPK, TUTTI, MEIKI,KEA, King Slide, REPON, TITUS, ITALIANA FERRAMENTA, LS Lighting, Sugatsune, SUSPA In addition to regular product displays, the exhibition will continue to feature diversified content and business opportunities through a variety of formats, such as the Business Package Plus (BPP) area, in-person business matching, offline-2- online live business matching, industry forum sessions, as well as conceptual spaces to promote the industry’s cutting-edge technology, and help companies respond to the shifting consumer demands. Return of “20 PLUS 20” Awards With the mission to uncover the most innovative furniture accessories and give recognition to the companies behind them, the "20 PLUS 20” Annual List will return once again to CIFM / interzum guangzhou in 2022. Details impart vitality to a piece of furniture, while design is the soul and materials form the backbone. A piece of furniture that pays attention to details can have long-lasting longevity in the continuously changing market. The 20 PLUS 20 Annual List – with origins from the influential “interzum Award” in Cologne, Germany – will feature the theme "In Pursuit of Furniture Accessories with Vitality" for 2021-2022. Compared with 70 per cent penetration rate abroad, China’s custom furniture market is still in its infancy. Through the contest, organizer Koelnmesse aims to encourage accessory makers to create functional yet novel and aesthetically pleasing products. Calls for 2021-2022 nominations are currently underway. Winning products will be showcased at the 20 PLUS 20 feature display to serve as inspirations for the industry. Industry engagement - Innovation forum Traditional manufacturing model and product functions have gradually been unable to meet the needs of the times. Product features are becoming increasingly diverse, and the introduction of smart products has become an inevitable trend. The further integration of technology and practical functions of furniture products is poised to become a new area of growth for the industry. Innovation drives development. Revolving around the topic "Vitality of Sustainable Innovation to Life", the interzum guangzhou 2022 forum will see the gathering of business representatives, renowned designers and trend experts to examine ways to inject life into furniture through design and technological innovation. Learn more about CIFM / interzum guangzhou at www.interzum-guangzhou.com. Source : interzum guangzhou

Greeting form Mr.Sam Chen

- 2021-09-29

The quality of Taiwan furniture has improved and market demand has increased year by year. Advanced technology has allowed machines to change the way of traditional furniture production, from traditional decorators to fully automated production of machines. The software has increased the utilization rate and reduced the production error rate. To satisfy consumers' needs for furniture styles and functions is all due to the upgrade of woodworking machinery. Taiwan woodworking machinery plays an important role. I am very pleased that through the publication of the Woodworking Machinery Magazine, Taiwan's furniture and woodworking machinery industry will be more closely linked, from the message end to the product end, to provide an information exchange platform for the furniture industry. The Chairman of Taiwan Furniture Manufacture Association( TFMA) Sam Chen

Greeting from Dr.Chi Hsiung Chen

- 2021-09-28

The development of an industry is very important for the transmission and connection of information. From the early days of international individual combat to the international group combat method that has evolved in the past 30 years, the Taiwan woodworking machinery industry has repeatedly achieved brilliant results. This year, Woodworking Machinery Magazine has undertaken the important task of simultaneously publishing online media and physical paper copies facing the challenges of the new epidemic era. In today's information environment, it is really not easy to run a magazine. First of all, I would like to congratulate the "Woodworking Machinery Magazine" for finally launching under the eager expectations of the industry. It is self-evident that it will serve as a platform for buyers, machinery related companies and woodworking practitioners to redefine and open up the development of Taiwan's woodworking machinery industry. New era. At the time when the third wave of the international epidemic broke out again and the launch of the first issue was imminent, I would also like to express my sincere blessings in addition to admiration. By Chi-Hsiung Chen Chair Professor of Asia University

The world furniture industry under the COVID-19 epidemic

- 2021-09-09

On the day of Teacher’s Day on September 28, 2020, the number of deaths due to the COVID-19 epidemic in the world exceeded one million. Affected by this epidemic, people’s lifestyles may be changed, including daily social interaction, work, shopping, communication and entertainment, etc., but also derived New demand business opportunities (Stephen Su et al., 2020). For example, the number of shoppers in stores in various countries has dropped sharply, from -32% in China to -80% in Mexico, physical stores have been hit, and the online shopping market has been greatly affected during the epidemic. Expansion (Laura Jones et al., 2020). In the six months since the outbreak of the epidemic, the global border blockade and crowd control have affected the furniture industry. For example, the well-known international furniture sofa NATUZZI was affected by COVID-19. The overall sales in September 2020 were 33.1% less than the same period in 2019 (Slaughter , 2020), Bassett furniture sales in the third quarter also fell by 16.3% (Russell, 2020). Therefore, this article does a little discussion on the world's furniture production and consumption in order to understand the current situation.

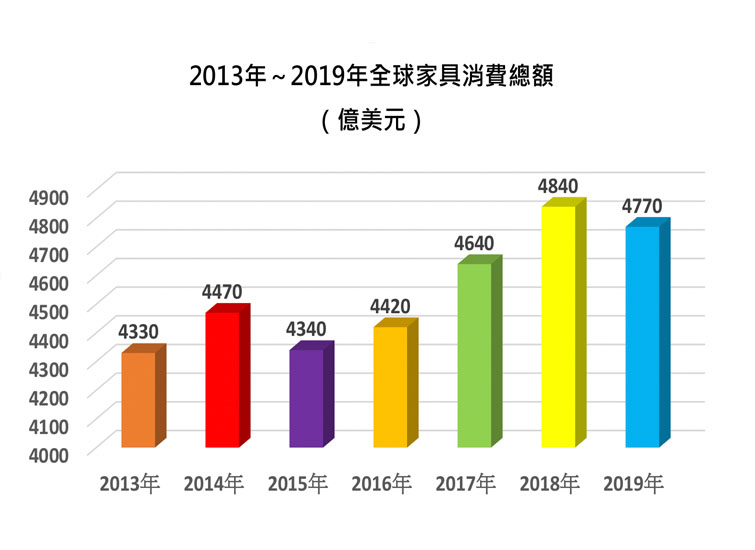

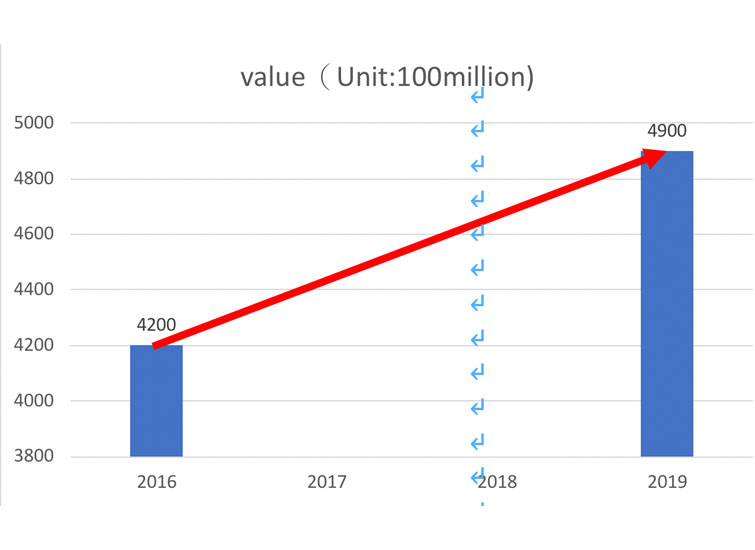

In the past 10 years, the international furniture trade has grown significantly. According to Centro Studi Industrial Leggera, (CSIL), the world furniture industry production value reached US$490 billion in 2019, and the world furniture consumption value reached US$ US$477 billion is shown in Figure 1 and Figure 2 (Finance, 2020), which contributes about 1% to the overall manufacturing industry’s international trade each year.

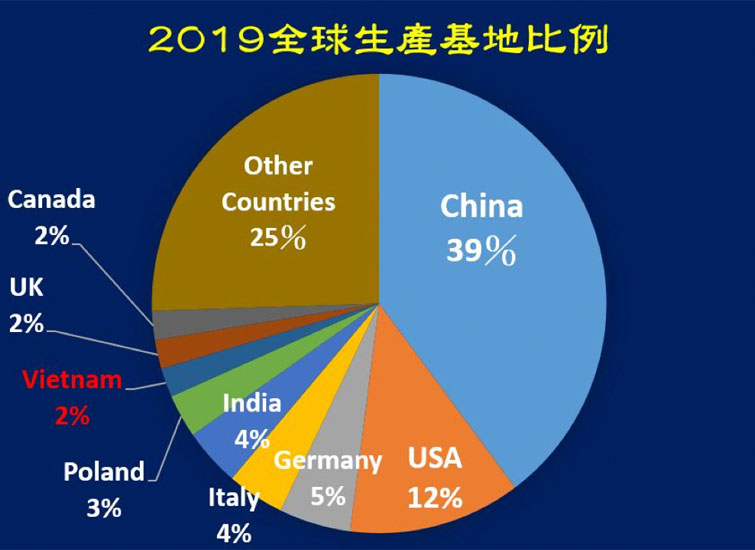

In the era of globalization, several countries have kept a pace of progress and have maintained global furniture production bases for many years. Figure 3 shows the proportion of furniture production in each region.

In the era of globalization, several countries have kept a pace of progress and have maintained global furniture production bases for many years. Figure 3 shows the proportion of furniture production in each region.

At present, China is still the largest furniture producer, accounting for 39%. The other major producers are the United States, Germany, Italy, India, Poland, Japan, Vietnam, the United Kingdom and Canada in order. However, Vietnam has gradually become the world's manufacturing factory. Especially in 2018, due to Trump's trade policy, a large number of China furniture factories migrated to Vietnam for production. Vietnam has become the world's seventh largest wooden furniture production base (CSIL, 2019). Sustained demand increases and plays an important role in the world's furniture production.

In the past 10 years, China has witnessed an unprecedented growth period in global furniture production. China has become a world leader in furniture production. This substantial growth has been accompanied by export-driven, industrial production, foreign investment, and abundant human capital and low-cost production have made China highly competitive in the international market. This competitiveness is due to the large-scale migration of Taiwanese furniture factories to Vietnam in 2000, and the large-scale migration of mainland-funded furniture factories to Vietnam in 2018. China’s competitiveness is decreasing year by year.

In the past 10 years, the United States has been the engine for the growth of furniture on the international stage. However, its growth depends on low labor cost suppliers such as China, Vietnam, Indonesia, etc. This has led to the closure of many furniture factories in the United States and the gradual weakening of the American furniture industry. Interestingly, high-quality furniture made of precious wood and carved is imported from China from neighboring countries such as Vietnam and Malaysia (Csanady et.al., 2019).

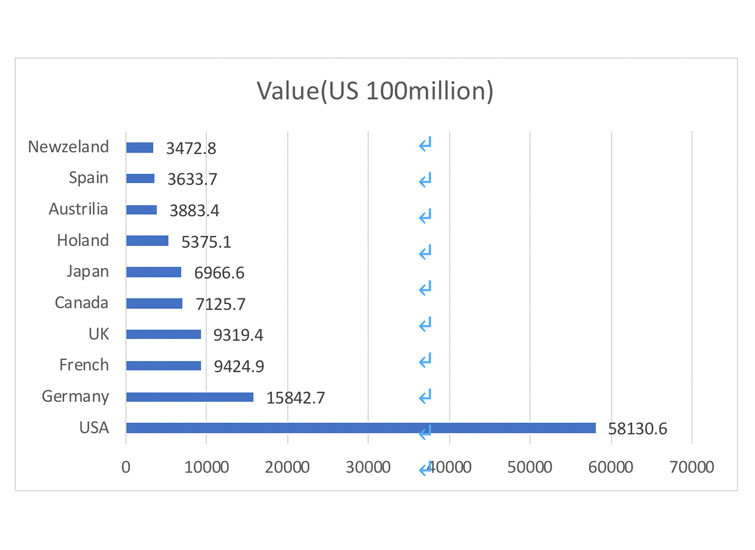

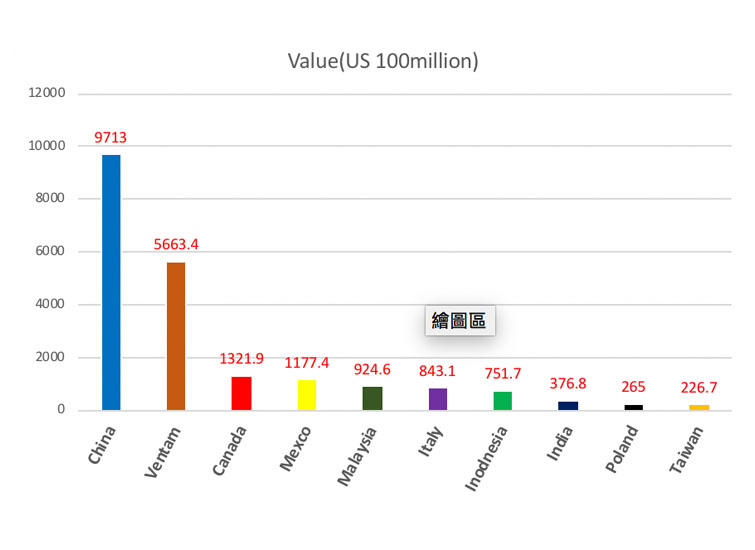

Based on the above, according to the "2019 Global Furniture Development and Outlook" research report released by the International Industrial Research Center (CSIL, 2020), in 2019, the United States will still be the world's largest furniture importer, followed by Germany, France, the United Kingdom and Canada. Europe and the United States are the world's major furniture consumers, and the top 10 sources of imported furniture from the United States are China and Vietnam, as shown in Figure 4 (Statista, 2020a) and Figure 5 (Statista, 2020b).

At present, China is still the largest furniture producer, accounting for 39%. The other major producers are the United States, Germany, Italy, India, Poland, Japan, Vietnam, the United Kingdom and Canada in order. However, Vietnam has gradually become the world's manufacturing factory. Especially in 2018, due to Trump's trade policy, a large number of China furniture factories migrated to Vietnam for production. Vietnam has become the world's seventh largest wooden furniture production base (CSIL, 2019). Sustained demand increases and plays an important role in the world's furniture production.

In the past 10 years, China has witnessed an unprecedented growth period in global furniture production. China has become a world leader in furniture production. This substantial growth has been accompanied by export-driven, industrial production, foreign investment, and abundant human capital and low-cost production have made China highly competitive in the international market. This competitiveness is due to the large-scale migration of Taiwanese furniture factories to Vietnam in 2000, and the large-scale migration of mainland-funded furniture factories to Vietnam in 2018. China’s competitiveness is decreasing year by year.

In the past 10 years, the United States has been the engine for the growth of furniture on the international stage. However, its growth depends on low labor cost suppliers such as China, Vietnam, Indonesia, etc. This has led to the closure of many furniture factories in the United States and the gradual weakening of the American furniture industry. Interestingly, high-quality furniture made of precious wood and carved is imported from China from neighboring countries such as Vietnam and Malaysia (Csanady et.al., 2019).

Based on the above, according to the "2019 Global Furniture Development and Outlook" research report released by the International Industrial Research Center (CSIL, 2020), in 2019, the United States will still be the world's largest furniture importer, followed by Germany, France, the United Kingdom and Canada. Europe and the United States are the world's major furniture consumers, and the top 10 sources of imported furniture from the United States are China and Vietnam, as shown in Figure 4 (Statista, 2020a) and Figure 5 (Statista, 2020b).

During the period of the epidemic, changes in living or working patterns may affect the design or functional requirements of furniture, and even the transformation of furniture patterns. Here are two cases. One is "Work-from-home". The lockdown of the epidemic has caused a rapid increase in work-from-home. It seeks to connect with colleagues, friends, school or family, and begins to think about what crisis to face. The UniFor company of the Molteni group of companies in Italy stated that after the epidemic, about 33% of the company's employees went to work and about 45% of the remaining home workers (Guzzine, 2020). This type of home work has created a market demand for home office furniture (Home-office-furniture). According to the CSIL (2020) survey of the European home office furniture market, this demand comes from people who often or occasionally work at home. It is estimated The potential number of people working at home in Europe is 830 million, of which Germany, the United Kingdom, and France rank among the top 3 (Figure 6). As the European market traditionally uses Ready-to-assemble-furniture and low-budget furniture, this wave of epidemic is bound to have a significant impact.

During the period of the epidemic, changes in living or working patterns may affect the design or functional requirements of furniture, and even the transformation of furniture patterns. Here are two cases. One is "Work-from-home". The lockdown of the epidemic has caused a rapid increase in work-from-home. It seeks to connect with colleagues, friends, school or family, and begins to think about what crisis to face. The UniFor company of the Molteni group of companies in Italy stated that after the epidemic, about 33% of the company's employees went to work and about 45% of the remaining home workers (Guzzine, 2020). This type of home work has created a market demand for home office furniture (Home-office-furniture). According to the CSIL (2020) survey of the European home office furniture market, this demand comes from people who often or occasionally work at home. It is estimated The potential number of people working at home in Europe is 830 million, of which Germany, the United Kingdom, and France rank among the top 3 (Figure 6). As the European market traditionally uses Ready-to-assemble-furniture and low-budget furniture, this wave of epidemic is bound to have a significant impact.

The second is furniture hygiene become more important in the post-epidemic era. In large open spaces such as community centers, shopping malls, universities, stations, airports, and hospitals, the public furniture must be cleaned, disinfected and maintained properly and regularly. To meet the above requirements, attention should be paid to furniture installation or design and manufacturing:

1. Material selection: leather and cloth lining furniture tend to accumulate bacteria in cracks and wrinkles, while wood is used

This problem can be avoided, and the wood has natural antibacterial and antimicrobial properties, and the surface of the material dries quickly

Speed, unfavorable to the growth of bacteria.

2. Modular design: easy to clean the corners and gaps of furniture, providing a high degree of hygiene, safety and reliability environment. Modular design can also be flexible and free to design new shapes according to space or environmental to match the needs. Figure 7 shows a case of modularization of the Skane University Hospital in Sweden, and its public space. The chair brings the beauty of natural materials, and the product is easy to disinfect and maintain. This seat system can be Individually plan and improve the working environment (Kamel, 2020)

The second is furniture hygiene become more important in the post-epidemic era. In large open spaces such as community centers, shopping malls, universities, stations, airports, and hospitals, the public furniture must be cleaned, disinfected and maintained properly and regularly. To meet the above requirements, attention should be paid to furniture installation or design and manufacturing:

1. Material selection: leather and cloth lining furniture tend to accumulate bacteria in cracks and wrinkles, while wood is used

This problem can be avoided, and the wood has natural antibacterial and antimicrobial properties, and the surface of the material dries quickly

Speed, unfavorable to the growth of bacteria.

2. Modular design: easy to clean the corners and gaps of furniture, providing a high degree of hygiene, safety and reliability environment. Modular design can also be flexible and free to design new shapes according to space or environmental to match the needs. Figure 7 shows a case of modularization of the Skane University Hospital in Sweden, and its public space. The chair brings the beauty of natural materials, and the product is easy to disinfect and maintain. This seat system can be Individually plan and improve the working environment (Kamel, 2020)

In short, the COVID-19 epidemic has not yet eased, material supply and furniture demand are uncertain. The main production bases of Taiwanese furniture such as China, Vietnam, Malaysia, Indonesia, etc., are also affected by the epidemic, and production capacity is full of variables. Faced with the coming of the post-epidemic era , The furniture industry may need to rethink the expansion of digital processing applications, the use of low-environmental impact creative materials, and the health of employees more important than the company’s production capacity to meet the development of the new world furniture industry after the epidemic.

about the auther :

Professor, Wen-Ching Su

Furniture Engineering & CNC Technology

Dept. of Wood Based Materials and Design

National Chiayi University

Reference

1. Finance (2020) global furniture industry market status and development trend analysis.

Website: https://read01.com/BJK54xj.html#.XxqAwZ4zY2w。ClickClick on Aug 20th 2020

2. (Lora Jones, David Brown & Daniele Palumbo)(2020)The new crown epidemic hits the world economy, nine pictures at a glance

。BBC NEWS Chinese Version。

Website: https://www.bbc.com/zhongwen/trad/business-53249104。

Clikc on Aug 29th 2020。

3. (Stephen Su et al., 2020)Key report on the impact of the global pneumonia epidemic (COVID-19) on Taiwan's industries。IEK Industry Information Network.Website:

https://ieknet.iek.org.tw/iekrpt/rpt_open.aspx?actiontype=rpt&indu_idno=0&domain=0&rpt_idno=422294729。

Click on Sep 20th 2020。

4. Csanady, E., Z. Kovacs, E. Magoss, J. Ratnasingam (2019) Furniture

Production Processes :Theory to Practice. Optimum Design and

Manufacture of Wood Products. Springer Nature Swizerland.

5. CSIL(2020)World Furniture Outlook 2020/2021.

Website: https://www.moneydj.com/KMDJ/News/NewsViewer.aspx?a={bd684700-7279-4bb9-bea2-99fd6f50c493}.

Click on Aug 20th 2020.

6. CSIL(2020)Home office furniture market in Europe. Website:

https://www.worldfurnitureonline.com/research-market/the-european-market-home-office-furniture-0058515.html.

Click on Sep 26th 2020.

7. Guzzini, G. (2020) COVID-19 will change forever the industry of furniture, according to entrepreneurs. Website: https://www.domusweb.it/en/speciali/domusfordesign/2020/the-things-that-covid-19-will-change-forever-according-to-entrepreneurs-in-the-furnishing-world.html. Click on Sep 30th 2020.

8. kamel, A. (2020) Furniture hygiene in a post COVID-19 era. Website: https://greenfc.com/stories/furniture-hygiene. Click on Sep 16th 2020.

9. Russell, T.(2020) Bassett Furniture reports 16.3% drop in Q3 sales.

FurnitureToday. Website: https://www.furnituretoday.com/financial-results/.

Click on Oct 1st 2020.

10. Slaughter, P. (2020) Natuzzi Q2 sales off by a third. Furniture Today.

Website: https://www.furnituretoday.com/financial-results/natuzzi-q2-sales-off-by-a-third/. Click on Sep 29th 2020.

11.Statista (2020a) Leading 10 source countries of household furniture imports in the U.S. 2019.

Website: https://www.statista.com/statistics/673244/leading-source-countries-of-household-furniture-imports-us/

Click on Sep 16th 2020.

12.Statista (2020b) Leading importers of furniture worldwide 2018.

Website: https://www.statista.com/statistics/673244/leading-source-countries-of-household-furniture-imports-us/

Click on Oct 1st 2020.

In short, the COVID-19 epidemic has not yet eased, material supply and furniture demand are uncertain. The main production bases of Taiwanese furniture such as China, Vietnam, Malaysia, Indonesia, etc., are also affected by the epidemic, and production capacity is full of variables. Faced with the coming of the post-epidemic era , The furniture industry may need to rethink the expansion of digital processing applications, the use of low-environmental impact creative materials, and the health of employees more important than the company’s production capacity to meet the development of the new world furniture industry after the epidemic.

about the auther :

Professor, Wen-Ching Su

Furniture Engineering & CNC Technology

Dept. of Wood Based Materials and Design

National Chiayi University

Reference

1. Finance (2020) global furniture industry market status and development trend analysis.

Website: https://read01.com/BJK54xj.html#.XxqAwZ4zY2w。ClickClick on Aug 20th 2020

2. (Lora Jones, David Brown & Daniele Palumbo)(2020)The new crown epidemic hits the world economy, nine pictures at a glance

。BBC NEWS Chinese Version。

Website: https://www.bbc.com/zhongwen/trad/business-53249104。

Clikc on Aug 29th 2020。

3. (Stephen Su et al., 2020)Key report on the impact of the global pneumonia epidemic (COVID-19) on Taiwan's industries。IEK Industry Information Network.Website:

https://ieknet.iek.org.tw/iekrpt/rpt_open.aspx?actiontype=rpt&indu_idno=0&domain=0&rpt_idno=422294729。

Click on Sep 20th 2020。

4. Csanady, E., Z. Kovacs, E. Magoss, J. Ratnasingam (2019) Furniture

Production Processes :Theory to Practice. Optimum Design and

Manufacture of Wood Products. Springer Nature Swizerland.

5. CSIL(2020)World Furniture Outlook 2020/2021.

Website: https://www.moneydj.com/KMDJ/News/NewsViewer.aspx?a={bd684700-7279-4bb9-bea2-99fd6f50c493}.

Click on Aug 20th 2020.

6. CSIL(2020)Home office furniture market in Europe. Website:

https://www.worldfurnitureonline.com/research-market/the-european-market-home-office-furniture-0058515.html.

Click on Sep 26th 2020.

7. Guzzini, G. (2020) COVID-19 will change forever the industry of furniture, according to entrepreneurs. Website: https://www.domusweb.it/en/speciali/domusfordesign/2020/the-things-that-covid-19-will-change-forever-according-to-entrepreneurs-in-the-furnishing-world.html. Click on Sep 30th 2020.

8. kamel, A. (2020) Furniture hygiene in a post COVID-19 era. Website: https://greenfc.com/stories/furniture-hygiene. Click on Sep 16th 2020.

9. Russell, T.(2020) Bassett Furniture reports 16.3% drop in Q3 sales.

FurnitureToday. Website: https://www.furnituretoday.com/financial-results/.

Click on Oct 1st 2020.

10. Slaughter, P. (2020) Natuzzi Q2 sales off by a third. Furniture Today.

Website: https://www.furnituretoday.com/financial-results/natuzzi-q2-sales-off-by-a-third/. Click on Sep 29th 2020.

11.Statista (2020a) Leading 10 source countries of household furniture imports in the U.S. 2019.

Website: https://www.statista.com/statistics/673244/leading-source-countries-of-household-furniture-imports-us/

Click on Sep 16th 2020.

12.Statista (2020b) Leading importers of furniture worldwide 2018.

Website: https://www.statista.com/statistics/673244/leading-source-countries-of-household-furniture-imports-us/

Click on Oct 1st 2020.