Stellar results of CIFM / interzum guangzhou 2021 bolstered by strong economic

- 2021-05-24

Asia’s largest and most comprehensive woodworking machinery, furniture production and interiors trade fair drew to a successful close on Mar 31 in Guangzhou, China.

With the partnership of two major exhibition forces – Koelnmesse and the China Foreign Trade Centre (Group) – CIFM / interzum guangzhou 2021 boasted a scale of 340,000 square meters with 2,100 exhibiting companies covering six key product categories.

Internationally renowned brands at the event included: HOMAG, Biesse, Cefla, IMA, SCM, WEINIG, Heveaboard, Impress, Kronospan, Lamigraf, PFLEIDERER, REHAU, Schattdecor, LG, Hyundai, LINAK, LIMOSS, OKIN, Henkel, SABA, Arpico, Italiana Ferramenata, King Slide, Repon and Sugatsune.

Nearly 200,000 visitors were drawn to the southern Chinese city to participate in the event – an increase of over 20 percent compared with the last edition.

“Visiting interzum guangzhou 2021 was to me an eye-opener towards how closely our economies are intertwined – not just in the field of automotive or high-tech: China is a major market for German hardwoods, which have been grown in ecologically sustainable forestry, and of indispensable components such as glues, coatings and hinges which are indispensable for producing furniture in the legendary German quality, highly appreciated by Chinese customers,” complimented the German Consul General in Guangzhou, Mr. Martin Fleischer, who was invited to visit the show.

Mr. Matthias Haasler, CEO of Rehau in Greater China and North East Asia said: “This is a good place to show new developments and really to go into good discussions with the customers here.

The industry has also seen and experienced interzum guangzhou over the past years. It is a very important place to meet and to see new products coming up. Being here is important – to simply show your strengths and to show the power.”

Ms. Vika Pesenti from Italiana Ferramenta was equally pleased: “I think it was very great to see so many people this year, so for us it was a very big advantage. We got a lot of visitors coming, and especially the first day we have registered about one thousand people coming to our stand. It was a great success!”

CIFM / interzum guangzhou is not only an important platform for visitors to discover and understand new products, but also allow exhibitors to gain insight into new market needs and lead the development of the industry.

Mr. Liu Chenglong, Project Manager of woodworking machinery manufacturer SCM, said: "We’ve made good gains at the exhibition. Visitor flow is relatively heavy. We’ve also met a number of new customers and got to know some new needs."

As the industry's flagship exhibition, CIFM / interzum guangzhou has always been a stage for the furniture industry to showcase new technologies, new products and new trends, and create business opportunities.

The 20 PLUS 20 Annual List for outstanding furniture accessories is a tribute to enterprises that are actively exploring creative solutions and keen to innovate. The 2019-2020 awards ceremony was held on the first day of the exhibition with 15 exhibitors receiving the accolade.

A dedicated showcase featuring 2018-2020 awarded products were also on display, allowing show participants to review the innovative development of the industry

in recent years. In addition, nominations for the 2021-2022 list is also officially open for exhibitors in 2022.

With the debut of the Business Package Plus (BPP) to assist affected overseas brands maintain their presence at the show, buyers were still able to continue to source innovative products and solutions from all over the world.

Also held at the BPP zone by the Agricultural Trade Office of the US Consulate General in Guangzhou, a seminar themed "Back to Nature - Modern Wood Structure" was streamed live on the online conference platform and received encouraging response.

Over at the PIAZZA lounge, a series of forums surrounding topics such as smart home systems, home lighting, furniture lifting technology, and new materials and technologies saw experts of the respective industry verticals sharing application cases and imparting valuable knowledge to attendees to quickly understand the high-quality products and innovative technologies of the industry, and promote the development of smart furniture.

A total of 124 online and offline business matching meetings were successfully conducted over the four-day period.

Impressed by the results, Mr. Li Lin, Strategic Purchasing Manager of Oppein – Asia’s leading cabinetry manufacturer based in China - said: "The business matching event is able to efficiently match our needs to the right suppliers. We have met some excellent companies, and will continue to follow up with these new contacts. The event format is brilliant."

"interzum guangzhou is one of the most important exhibitions of the year for us. It is a platform to find new suppliers and interact with the industry. We participate in the business matching activities every year, and this year is no exception. Everything took place very smoothly, from the pre-show selection of suppliers to the on-site coordination arrangements, greatly improving communication efficiency. We’ve also received some good results. Thanks to the organizers for their professionalism and meticulous efforts," commented Mr. Li Peng, R&D Director of well-known custom furniture maker Vifa.

After enjoying similar good outcome, Mr. Engarafat Alharahsheh, General Manager of SAS-TECH INDUSTRIAL GROUP LTD was quite satisfied: “The event was good and well organized with professional service. For sure I will join next year.”

Affected by the pandemic, Mr. Nilesh Kumar, owner of Mayur from India, was unable to visit the exhibition in person. Making use of the online business matching for the first time, he expressed his delight at the unexpected results:

"Before trying this out, I was unsure if I could seriously meet any of the manufacturers...(but) I really enjoyed the session and have gotten new

manufacturers and suppliers who could help me out. Thanks to the team for their awesome work, and I would recommend for others to try this out."

The next edition of CIFM / interzum guangzhou slated to take place from March 28 – 31, 2022.

Learn more about interzum guangzhou 2022 at www.interzum-guangzhou.com.

Source:CIFM / interzum guangzhou 2021

WOOD AND FURNITURE TECHNOLOGY: STRONG REBOUND IN THE FIRST QUARTER 2021

- 2021-05-24

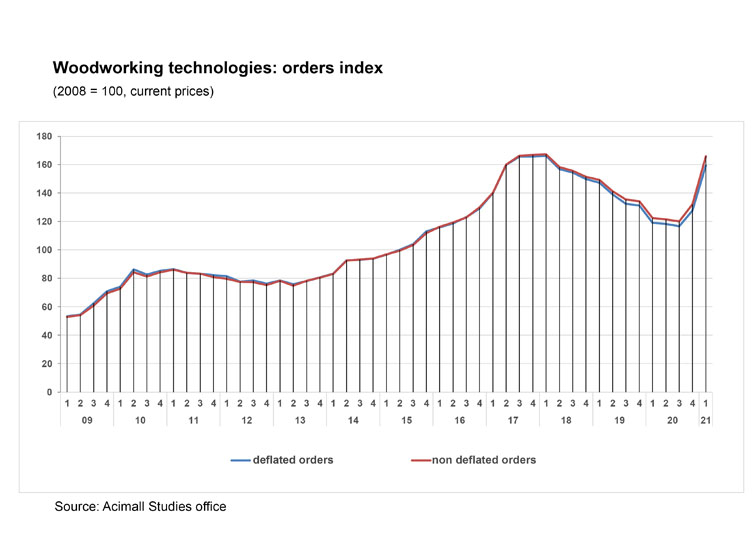

“There never could be a better way to start the new year. The data processed by our Studies office confirm the "strong perception" of recent months: 2021 has started off very positively, with a strong expansion of the demand of furniture and wood industry technology”. Luigi De Vito, president of Acimall – the association that gathers the Italian manufacturers of technologies, tools and equipment for wood and wood-based materials – commented the amazing result of the first ninety days of this year, with orders up by 58 percent compared to the same period of 2020. The trend of international orders was very positive, with a 52 percent increase, while domestic demand literally boomed, growing by 87.8 percent.

“The term of comparison is clearly a period – January-March 2020 – that had been strongly affected by the lockdown caused by the global sanitary emergency, but nevertheless, the rebound has largely exceeded our expectations, supported by the positive signals that had come in the final quarter of 2020”, De Vito added.

In absolute value, the excellent trend of orders in early 2021 has pushed the Italian wood technology industry back up to its al-time highs, achieved in 2018, with a quarter-on-quarter increase by 17.6 percent.

The quarterly survey carried out by Acimall’s Studies office on a statistic sample of companies also shows that the orders book covers 4.1 months, while price variation since January 1 amounted to one percent. Total revenues, compared to Q1 2020, increased by 2.4 percent.

The interviewees gave clear feedback in the quality survey: 75 percent of the sample indicated a positive production trend (versus 50 percent in the previous quarter, clear evidence of increasing confidence in more "reactive" markets"); 5 percent reported decreasing business, while 20 percent reported substantial stability. Growth was also the predominant trend in employment figures: 55 percent of the sample reported a stable trend, while 40 percent indicated an increase and 5 percent a reduction. Available stocks are increasing according to 40 percent of the interviewees, decreasing for 20 percent and stable for 40 percent.

According to the forecast survey, 55 percent expect the export trend to remain unchanged at the current values, while 45 percent believe that the situation can only improve. No one fears the situation might get worse, which is significant in terms of confidence in the future. Looking at the domestic market alone, the outlook is the opposite: 55 percent of the sample expect further expansion, 40 percent stability and 5 percent think there will be a reduction.

2020 FINAL BALANCE

So, the first quarter showed a clear and positive change of direction after a year, 2020, that will be remembered as one of the most difficult periods our industry has ever faced.

According to the final figures published by the Acimall Studies office, the production of Italian companies in 2020 stopped at 1,848 million euro, i.e. 18.4 percent less than in 2019. This massive drop, as it could be easily predicted, mostly occurred in the first part of the year, when the impact of the measures to fight the Covid-19 pandemic was stronger. Starting from the summer, the trend was much more positive, especially in the fourth quarter; the trend reversal supported confidence and a positive attitude across the entire industry, but it was not enough to make up for lost time, orders and revenues, although it helped close 2020 better than it had been figured out in the toughest months.

Of course, the global situation also had an impact on Italian export, with a 15.8 percent decrease versus 2019 and an absolute value of 1,330 million euro. Despite this reduction, international sales remain the major driver for the entire industry. The reduction of import in 2020 was even stronger in percentage, down by 28.2 percent, at 153 million euro. On the whole, these figures indicate that the domestic demand in 2020 was still in a critical situation, while the trade balance – i.e. the export-import difference – still remained at high levels (1,177 million euro).

Source:ACIMALL

WOOD TAIWAN Digital Days

- 2021-04-15

WOOD TAIWAN Digital Days, from April 22nd to 25th, 2021, will keep you updated on the latest development about Taiwan woodworking machinery. With major economies implementing loose monetary policies and the support of their housing market boom, demand for this industry still exists, and purchase orders from the ASEAN market have also surged. Tailored to customer’s needs, Taiwan’s machines enjoy a good reputation of high quality, reliability, and quick response to users’ business demands after their sales. Taiwan is your best partner for woodworking manufacture.

WAFERLOCK in the Central Taiwan Science Park has attained both USA LEED Platinum certification and Taiwan Intelligent Building Diamond certification.

- 2021-04-14

WAFERLOCK in the Central Taiwan Science Park is the only factory office building that has attained both USA LEED Platinum certification and Taiwan Intelligent Building Diamond certification. In addition, it ranks the highest score among all projects which have applied for LEED in Taiwan. (84 credits, higher than other well-known companies such as ASE Technology, AU Optronics, Asus)

The office building itself not only adopts an energy-saving system and green materials, but also boasts many advantages including: 100% rainwater reuse to water plants and flush toilets, 24 hour indoor air quality monitoring with energy-saving AC equipment to automate fresh air exchange, the windows are positioned to align with the path of the sun's movement during the day in accordance with the client's wishes, a west-facing green wall preventing western exposure, Alclad siding to obstruct heat conduction and mineral wool lining to cool down indoor temperature and reduce energy-waste, placing solar panels on the roof to block out direct heat from the sun, the application of advanced technologies such as automatic devices, facial recognition system, industry 4.0 and robotic arms.

All of these advantages are the visible highlights, but what makes WAFERLOCK stand out is the source management. Unlike others, they decided to pursue green building from the beginning of the design process. Then, in conjunction with construction management, the application of smart devices to manage the building and of course, most importantly, teamwork, WAFERLOCK was able to simultaneously achieve both certifications.