Joe Chang proposes strategies to meet challenges

- 2022-04-23

Although the epidemic situation has increased, the operation of the Taiwan Woodworking Machinery Industry Association(TWMA) is still actively carried out, but in order to cooperate with epidemic prevention, the second board of directors and supervisors adopted an online meeting. During the meeting, the new chairman Joe Chang pointed out the challenges that Taiwan woodworking machinery will face in the future, and proposed For future countermeasures, he emphasized Taiwan's competitive advantages. He also thanked the new team for their collective efforts to accomplish the mission of the WOOD TAIWAN Digital Go, digital marketing, handover ceremony and other conference affairs currently being implemented.

Chairman Chang said that in 2020 and 2021, COVID-19 will disrupt the normal activities of the world. Coupled with the Sino-US trade war, the United States began to impose a 25% tariff in 2018. Taiwan's woodworking machine industry has benefited from the "home economy" phenomenon. In 2020, the export has grown by 21.49% compared with 2019, and by 26.8% in 2021. The export value has reached 903 million US dollars, or about NT$25 billion, which has made the new record.

But in the future, Taiwan's woodworking machinery industry still faces many challenges:

1. Woodworking machinery in mainland China continues to strengthen and expand its equipment and market optimization. In addition, several large companies in China are moving towards group management, and the global layout is getting stronger and stronger, which compresses the living space of woodworking machinery in Taiwan. In 2008, exports surpassed Taiwan and rose to the third place. In 2020, it will surpass Germany to become the world's number one.

2. The export market ratio is too dependent on the United States: the proportion is 40% in 2015, and it will increase to 63% in 2021, and DIY is estimated to account for about two-thirds, this is also something to worry about.

3. The third generation succession problem: Most of Taiwan's woodworking machinery manufacturers are small family-owned enterprises, and most of the second generation belong to the X generation (1964~1980). For the Y generation (1980~1990) or the Z generation (1990~2010), there is a lack of interest in manufacturing. In 2006, there were still 282 member manufacturers of the guild, and by 2022, it will be reduced to 239.

4. The production equipment is still dominated by stand-alone machines, and most of the machines still lack smart machinery elements: with future trends, there will be smart machines, smart whole lines, and smart factories. If manufacturers do not invest in the layout and participate in it, they will be limited by the market sooner or later, or even eliminated.

Joe quoted the famous saying in Jurassic Park, "Life will find its own way." Most Taiwan woodworking machinery manufacturers still have the gene of "tenacity and fearlessness" in their blood, and they are willing to help each other and share experience. This is hard to see in other association.

In the future, Joe and TWMA directors and supervisors will unite and make selfless dedication on the basis of the good foundation established by the predecessors, and come together to tide over the difficulties with the member manufacturers. In the future, TWMA's goals are very clear: "Industry Niche Value-Added Innovation", "Smart Digital Development and Application", "Local Talent Selection and Cultivation", and "Mutual Support of Industry, Government, University, Research and Research" will allow Taiwan woodworking machinery industry to continue to grow globally. The stage shines brightly!

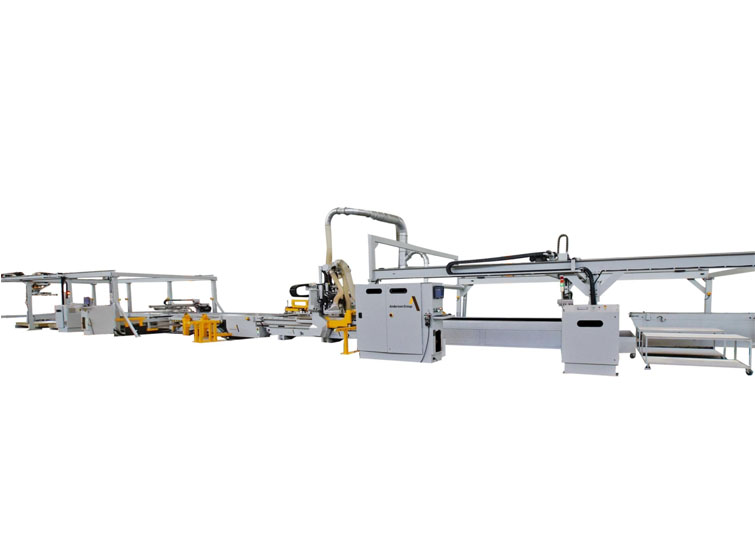

Smart Mechanized Nesting Production Line won the 2022 Taiwan Excellence Award

- 2022-04-18

Industry type:Productivity and energy

Product model number:STRATOS PRO FL

Anderson Industrial Corp.

About Anderson Industrial Corp.

Since 1972, Anderson has taken pride in its speed, service and the outstanding quality of its products.The company offers experience and expertise in the manufacturing of CNC machinery that few other companies can match.

In the near future, the company will continue to expand its operations to offer fast, efficient sales and service in markets throughout the world. Beyond that, the group is working to develop strategic agreements with key players in the global market. With Anderson core competency in CNC technology, we are able to use our profession to design and develop machines for a wide range applications and industries. Anderson’s commitment to excellence is shown in all of its divisions, each one offering its clients an innovative and high performance solution.

CNC Processing Center/Printed Circuit Boards/Print & Graphic/Key Component/Merchandise

About STRATOS PRO FL

STRATOS PRO FL is equipped with 1. Automatic tool length measurement (reduce manual measurement errors, rare in competitors). 2. Tool change function while machining, the machining efficiency is increased by 10% to 20% (not yet competitors have this function). 3. The whole board is suspended and loaded, positioning once, and the feeding speed is twice as fast, without scratching the work piece (the competitor is a drag type, which is low in efficiency and easy to scratch the work piece). 4. The height of the unloading table is automatically adjusted to improve the stability of the automatic unloading. 5. Graphical and intuitive operation interface (AGMVP independently developed by Anderson).

.jpg) http://www.anderson.com.tw

Source: Anderson group

http://www.anderson.com.tw

Source: Anderson group

Leadermac 4 Side Moulder won the 2022 Taiwan Excellence Award

- 2022-04-18

Industry type:Productivity and energy

Product model number:uPower

LEADERMAC MACHINERY CO., LTD.

1. Structure of the jumping spindle: it can cut the complex surface lines, could be furniture component or art accessories. Also this jumping spindle structure whiche control by the computer value(CNC,Computer Numerical Control), this can reduce the processing damage rate and increase working efficiency.

2. The operation interface using the HMI, it is easy to understand and operate through the graphical operate interface. All database including product, cutter tools, grinder data which gather in the HMI. The work product, order numbers, descriptive one by one shows out. Do not need to rely on the engineer memory to operate machinery. It is conveniences, speed, timeliness and variety small amount of rapid production; which may save time to get more order than others.

The above structure and function are closer to the needs of consumers, also increased the 4 side moulder its function; simplify the operation of the 4 side moulder, more in line with humanity needs.

http:// http://www.leadermac.com/

Source: Leadermac

BPW Taiwan hosts an on-line conference on “Women's economic empowerment pandemic

- 2022-03-22

The CSW66 Forum online conference, hosted by International Federation of Business and Professional Women (BPW Taiwan), Taipei Tenyuan club BPW,Taiwan, The theme of the conference is "Women's economic empowerment after Pandemic". The host is Ms.Chou. The speakers are Ms.Prati Maya Pun who is from Nepal, Ms.Ester Eomois who is from Estonia, Ms.Freda Miriklis who is from Australia and Ms.Winnie Chao who is from Taiwan.

.jpg) Ms. Freda Miriklis is from Australia and has 25 years of international development experience. She is recognized as a global advocate for women's empowerment. She explained that there are many international organizations that help women improve their economy and life.

Ms. Freda Miriklis is from Australia and has 25 years of international development experience. She is recognized as a global advocate for women's empowerment. She explained that there are many international organizations that help women improve their economy and life.

.jpg) Ms.Winnie Chao is Winnie, the voice representing Taiwan. She is not only a successful female entrepreneur, philanthropist, but also a mother of five children. It shows that the contribution and importance of women in education are also factors that affect the future development of a country. Winnie mentioned that last year due to the epidemic, the school's physical courses were forced to be changed to online teaching, but she also pointed out that children are studying at home, and parents must also see whether the child is focusing on the teaching. It is also expected to create opportunities for individuals to advance themselves , promote parental education , unify resources, and build sustainable networks. Winnine also encourage women to accept yourself, believe yourself , and be who you truly are and hope that every woman can achieve the goal of her life.

Ms.Winnie Chao is Winnie, the voice representing Taiwan. She is not only a successful female entrepreneur, philanthropist, but also a mother of five children. It shows that the contribution and importance of women in education are also factors that affect the future development of a country. Winnie mentioned that last year due to the epidemic, the school's physical courses were forced to be changed to online teaching, but she also pointed out that children are studying at home, and parents must also see whether the child is focusing on the teaching. It is also expected to create opportunities for individuals to advance themselves , promote parental education , unify resources, and build sustainable networks. Winnine also encourage women to accept yourself, believe yourself , and be who you truly are and hope that every woman can achieve the goal of her life.

.jpg) Ms.Ester Eomois from Estonia is the president of BPW Estonia. She has been researching the issue of "the careers paths of millennial generation female leaders " for a long time. During the talks, she provided the European Union's report on women's mental and worry load, , cognitive labor, household project management and unpaid and unnoticed work. Fortunately, Estonia’s national resources are relatively sufficient, and various infrastructures are relatively complete during the epidemic period, such as online shopping, e-doctor, e-schooling, entertainment, work, government services.. And the nursery homes were never fully closed during lockdowns and monthly fees were compensated by city governments. During full lockdown, food packages were prepared for take away for schoolchildren. BPW Estonia also continue to hold training programs.

Ms.Ester Eomois from Estonia is the president of BPW Estonia. She has been researching the issue of "the careers paths of millennial generation female leaders " for a long time. During the talks, she provided the European Union's report on women's mental and worry load, , cognitive labor, household project management and unpaid and unnoticed work. Fortunately, Estonia’s national resources are relatively sufficient, and various infrastructures are relatively complete during the epidemic period, such as online shopping, e-doctor, e-schooling, entertainment, work, government services.. And the nursery homes were never fully closed during lockdowns and monthly fees were compensated by city governments. During full lockdown, food packages were prepared for take away for schoolchildren. BPW Estonia also continue to hold training programs.

.jpg) Ms. Prati Maya Pun from Nepal also said that Nepal is a country dominated by agriculture, and its domestic resources are relatively insufficient. Nepalese women are still forced to interrupt their studies, so they are often unable to take up more professional jobs and pay more at work. In terms of women's weaker social status, Ms. Prati Maya Pun also suggested that women's economic empowerment can access to income and assets, control of and benefit from economic gains, and finally to get power to make decisions.

Ms. Prati Maya Pun from Nepal also said that Nepal is a country dominated by agriculture, and its domestic resources are relatively insufficient. Nepalese women are still forced to interrupt their studies, so they are often unable to take up more professional jobs and pay more at work. In terms of women's weaker social status, Ms. Prati Maya Pun also suggested that women's economic empowerment can access to income and assets, control of and benefit from economic gains, and finally to get power to make decisions.

.jpg) In the end, the host chou said that even though women's empowerment still has a way to go, but we are not alone. Many institutions and societies around the world are working hard to achieve this, and there are currently many female leaders in the world: such as Taiwan, Germany, Finland, Norway, Denmark, Iceland, New Zealand, etc., women's influence is not only resistant to COVID-19 and even war. Women, keep going!

In the end, the host chou said that even though women's empowerment still has a way to go, but we are not alone. Many institutions and societies around the world are working hard to achieve this, and there are currently many female leaders in the world: such as Taiwan, Germany, Finland, Norway, Denmark, Iceland, New Zealand, etc., women's influence is not only resistant to COVID-19 and even war. Women, keep going!

.jpg)

Joe Chang was elected as the chairman of the 7th TWMA, hoping to strengthen the enterprise's constitution through talent cultivation and digital marketing

- 2022-02-19

Taiwan Woodworking Machinery Industry Association (TWMA) held an extraordinary general meeting on February 18 at the Fengyuan Li Yan Banquet Hall. During the meeting, the most important thing was to elect a new team of directors and supervisors. Joe Chang, the general manager of Kuang Yung Machinery, was successfully elected as the chairman of the board, James Lin , the general manager of Jun Shiau machinery and Ian Chang , the general manager of INNOVATOR Machinery both were elected as the vice-chairman of the board. In his speech, Joe said that Taiwan's woodworking machinery exports grew by 21.49% in 2020 and 28% in 2021 against the trend. These impressive achievements are the results of the concerted efforts of Taiwan's woodworking machinery manufacturers. Looking forward to the future, Joe hopes to develop talents and digital marketing. Strengthen the corporate constitution, so that Taiwan's woodworking machinery industry can continue to lead and reach new heights. By NewsWin (星宇傳媒)

CATAS: A GREAT 2021. WORKING ON THE 2022!

- 2022-02-08

“The 2021 was a complicated, sometimes difficult year, which has tested our limits, there’s no doubt. A challenge that I must say Catas has passed, achieving important results on all issues on which it is committed”. Lucia Cristina Piu – President of Catas, the leading European laboratory for the wood-furniture sector – has no hesitation in commenting on the results achieved in the year just ended. A year of strengthening that confirms the renewed energy of the sector, rewarded by greater attention to the living environments, as well as to the issues of technical standardization, safety and certification. The 2021 year closes with a turnover that once again exceeds the threshold of 7 million euros, thanks to a growth of 6 percent in "subscribers" (Italian and foreign companies that have a regular collaboration with the laboratory), which have gone from 1,272 in 2020 to 1,345 last year. A figure confirmed by the growth in the tests carried out (52,218 in 2021 against 49,662 in 2020) and by the increase in the product certifications numbers (177 in 2021, 164 in 2020), with a strong relevance in particular for the "Made in Italy" certification. “A growth to which the opening of the Catas Point Pesaro has significantly contributed, the first in a series of contact points that will allow us to be increasingly present and proactive in the main furniture districts areas, thanks to which we have started collaborations with some of the most well-known brands of the national retail sector. A new scenario that has enabled Catas to communicate the value of its activities to the final consumers, the real end-users of our certifications”, Piu continued. The 2021 year has involved investments of more than 500 thousand euros in the expansion of the equipment both at the Catas Lissone site in Brianza (for test on furniture products) and in San Giovanni al Natisone in Friuli Venezia Giulia (for the chemical analysis). Concerning the training activities, Catas Academy has organized more than 30 events, in addition to many internship experiences with students from universities and high schools. A year that also saw the publication of the first “Edging Handbook”, edited in collaboration with Federchimica-Avisa, which makes a clear point in one of the fundamental steps in the furniture production process. Another significant news has been the launch of “The Life Cycle measured by CATAS”assessment service by which the laboratory offers an objective contribution to the issue of sustainability, providing companies in the sector with a rigorous tool for the measure of the environmental, social and energy “weight” of the products. These results will measure and represent the real effort of companies for a truly sustainable industry and economy. “Now we look to the future”, President Piu continued. “In 2022, health emergency permitting, the presence in Italy will be increased thanks to the roots in Friuli Venezia Giulia, in Brianza and in the large Pesaro furniture district”. “The organizational response to the growing needs from the clients will be a further important development step, with the enlargement of the Catas site in San Giovanni al Natisone – Piu concluded – where we will build a new three-storey building, covering an area of approximately 2,500 square meters, dedicated to laboratories for the fire reaction tests and mechanical tests on materials, components and adhesives for the furniture sector”. New plans are also being defined for the training services for technical schools and universities. In addition, a wide schedule of webinars will be held in the coming months with the collaboration of Federchimica and Acimall (the Italian Association of Woodworking Machinery Manufacturers) Since several years, Catas has also been designing, manufacturing and supplying test equipment for components, chairs, tables, beds and furniture, including turnkey. The offer is the result of the knowledge and experience gained over many years of activity and already represents a qualifying voice in the activity of the institution, on which in the future we will focus even more. In the light of this direction too, the new Catas Engineering catalog was developed containing this kind of offers.