Michael Chang 's six-year term expired and handed over a beautiful transcript

- 2022-01-17

Michael Chang served as the second terns chairman of the Taiwan Woodworking Machinery Industry Association TWMA. At the end of his term, in addition to expressing his support and trust for the advanced members and supervisors, he also hopes to continue to promote the reform of the association under the leadership of the new chairman in the future. and enhance the well-being of members. Looking back on the past six years, Michael Chang has handed over beautiful transcripts: including Through the exhibition and delegation visits, we expanded the interaction and communications with international associations and organizations, such as VDMA (Germany), ACIMALL (Italy), JWMA(Japan), LJWMCC(China), QDWMA(China), Nankang Furniture Association(China), HAWA (Vietnam), BIFA (Vietnam), and the TFMAVN (Vietnam). We also established the "Taiwan Woodworking Machinery Technology Center" at the HCMUTE (Vietnam) to enhance the visibility of Taiwan woodworking machinery in the international arena. We participate in the program with Ministry of Economic Affairs, TAITRA, Taichung City Government, and PMC so that the members can share government resources. We become a member of the Smart Machinery (Smart Manufacturing) promotion Associations and speak for the industry through relevant channels. We establish a virtual exhibition hall for woodworking machinery and lead Taiwan's woodworking machinery towards digitalization of marketing. We have also established links with the University of Technology and the Industrial Senior High School to nurture local young students to continue the development of woodworking machinery. With the approval of the general meeting, the office will be relocated to Taichung City Center, near the Taichung City Government, which creates good opportunities for interaction with the industry, government, and academia, to enhance the Association's external image. In terms of the overall global woodworking machinery industry, China's export ranking jumped to the world's first, followed by Germany, Italy, and Taiwan. There is still a lot of room for growth in Taiwan's woodworking machinery exports. European manufacturers are still in a leading position in the market due to the uniqueness and high quality of their products, but if Taiwan manufacturers want to improve their overall competitiveness, they should focus on the overall technological improvement and reduce the technological gap as the main goal. We will continue to expand the use of digital marketing strategies through online exhibitions and online seminars, and provide remote services through Virtual Reality (VR) and Augmented Reality (AR). Michael hope that Taiwan woodworking machinery will move toward intelligent machinery and digital transformation to produce more environmentally friendly and energy-saving machinery and create prosperity. By NewsWin

OAV: Constantly innovating and researching to maintain the leading position in the market

- 2022-01-06

I am very happy to interview Dennis Liu, general manager of OAV equipment and Tools Inc, following is the summary of the interview:

.jpg) Q1: I see you offer band saws, sliding table saws (panel saws), dust collectors ,what are your most popular machine categories?

Ans: Over the years our production has evolved to include more machinery for production use including automatic edgebanders and sliding table saws. We work closely with our distribution network to determine which machines are required by the end user and we develop machines to fit these needs. We are constantly evolving our products and our R&D team work closely with our sales department to ensure we are manufacturing the right machine at a price which is attractive to the market. We offer a wide product range within these categories in order to satisfy the needs of our users and their specific requirements.

Q2:How do you handle customer service for customers all over the world?

Ans: OAV has aligned ourselves with direct importers and distributors in different countries which not only stock and sell our product but also service it. They offer technical support and spare parts to the customer to ensure the optimal operation of our machinery. This is particularly important with regards to our edgebander and panel saw products and for over a decade we have aligned ourselves with agents to provide the customers with this service. We understand the importance of timely support and have put together a library of training videos and documents to ensure our distributor partners are fully versed in servicing our machines.

Q3: What can you tell customers to assure them about the capabilities and reliability of your machines?

Ans: OAV was established in 1980 with a goal to provide the highest level of customer satisfaction possible. This is our total focus and we have developed our organization around this goal. We invest continually in research and development, quality control, and education in order to ensure our team members achieve this goal. Our greatest strength at OAV is our dedication to offering the best possible service to meet the needs of customers all over the world. Our next plan is developing the ultimate edge bander with nimble functions, this invention and development will benefit customers and help OAV maintain the leadership in the market. Customizing with needs is the motivation and also the encouragement for new design. It is very important to have a clear blueprint which is pursuing OAV’s philosophy: “satisfy customers, satisfy employees, satisfy investors”

Q4: What new technology are you applying to your machinery?

Ans: Our edgebanders are available with a touch screen user interface. In addition to being more user friendly if offers additional diagnostic functions which provide specific warning information when an issue arrives. This allows for faster solutions when errors arise. Machine with touch screen display and PLC parameter setting on operation bring not only the stable working conditions but also the stable quality of your products. What’s more, patented parameter and barometric speed measurement system win the award from Taiwan woodworking machinery association. This choice is the best helper to optimize customers’ investment and take your organizational output and performance to the next level.

Q1: I see you offer band saws, sliding table saws (panel saws), dust collectors ,what are your most popular machine categories?

Ans: Over the years our production has evolved to include more machinery for production use including automatic edgebanders and sliding table saws. We work closely with our distribution network to determine which machines are required by the end user and we develop machines to fit these needs. We are constantly evolving our products and our R&D team work closely with our sales department to ensure we are manufacturing the right machine at a price which is attractive to the market. We offer a wide product range within these categories in order to satisfy the needs of our users and their specific requirements.

Q2:How do you handle customer service for customers all over the world?

Ans: OAV has aligned ourselves with direct importers and distributors in different countries which not only stock and sell our product but also service it. They offer technical support and spare parts to the customer to ensure the optimal operation of our machinery. This is particularly important with regards to our edgebander and panel saw products and for over a decade we have aligned ourselves with agents to provide the customers with this service. We understand the importance of timely support and have put together a library of training videos and documents to ensure our distributor partners are fully versed in servicing our machines.

Q3: What can you tell customers to assure them about the capabilities and reliability of your machines?

Ans: OAV was established in 1980 with a goal to provide the highest level of customer satisfaction possible. This is our total focus and we have developed our organization around this goal. We invest continually in research and development, quality control, and education in order to ensure our team members achieve this goal. Our greatest strength at OAV is our dedication to offering the best possible service to meet the needs of customers all over the world. Our next plan is developing the ultimate edge bander with nimble functions, this invention and development will benefit customers and help OAV maintain the leadership in the market. Customizing with needs is the motivation and also the encouragement for new design. It is very important to have a clear blueprint which is pursuing OAV’s philosophy: “satisfy customers, satisfy employees, satisfy investors”

Q4: What new technology are you applying to your machinery?

Ans: Our edgebanders are available with a touch screen user interface. In addition to being more user friendly if offers additional diagnostic functions which provide specific warning information when an issue arrives. This allows for faster solutions when errors arise. Machine with touch screen display and PLC parameter setting on operation bring not only the stable working conditions but also the stable quality of your products. What’s more, patented parameter and barometric speed measurement system win the award from Taiwan woodworking machinery association. This choice is the best helper to optimize customers’ investment and take your organizational output and performance to the next level.

.jpg)

Eumabois General Assembly 2021 A successful restart despite the Corona pandemic

- 2021-11-12

Eumabois, the European Federation of woodworking machinery and tools manufacturer, held its annual General Assembly on November 5th, 2021.

After substituting the onsite event with Eumabois first “Digital General Assembly” in 2020, the delegates and board members gathered again in presence in Vienna, hosted by the Austrian association FMTI, together with Eumabois president, Jürgen Köppel and the vice president, Luigi De Vito.

.jpg) The opening topic was the general outlook on the woodworking industry which has been showing a rapid and very positive recovery. The figures, despite the fact that also the woodworking industry suffers from high material costs and lack of raw material, indicate a sustained growth rate in the mid-term. The global demand remains high, as evidence of the good resilience of the sector in response to the crisis triggered by the Corona virus. Mega-trends such as digitalization and industrial automation, as well as a growing demand for home furniture and kitchens, stimulated by travel restrictions and the cocooning effect, are driving the woodworking industry, too.

Looking at the Eumabois Exhibition Network 2021, most of the shows have been canceled. On the other hand, a full calendar of trade fairs is planned for 2022 with two top exhibitions events: HolzHandwerk in Nuremberg in March and Xylexpo in Milan with a new date in October. The positive signals coming from the exhibition sector are an important step towards the normality confirming the value and relevance of face-to-face events.

The meeting in Vienna was also used to officially launch the new Eumabois website with completely renewed and modern graphics. There were also important news on the technical projects side.: OPCUA (Open Platform Communication Unified Architecture) got the marketing name “IZY”, which has been officially presented to the market during LIGNA.Innovation Network on September 27th, 2021.

At the end of the Assembly, the president Jürgen Köppel expressed his sincere thanks to the hosting association FMTI and to all the present national associations, stating: “…I firmly believe that one of the key pillars for the growth of our industry is our joint European approach.”

The next Eumabois General Assembly will be held on 22nd-23rd of September 2022 in the city of Krakow, Poland.

Source: Eumabois

The opening topic was the general outlook on the woodworking industry which has been showing a rapid and very positive recovery. The figures, despite the fact that also the woodworking industry suffers from high material costs and lack of raw material, indicate a sustained growth rate in the mid-term. The global demand remains high, as evidence of the good resilience of the sector in response to the crisis triggered by the Corona virus. Mega-trends such as digitalization and industrial automation, as well as a growing demand for home furniture and kitchens, stimulated by travel restrictions and the cocooning effect, are driving the woodworking industry, too.

Looking at the Eumabois Exhibition Network 2021, most of the shows have been canceled. On the other hand, a full calendar of trade fairs is planned for 2022 with two top exhibitions events: HolzHandwerk in Nuremberg in March and Xylexpo in Milan with a new date in October. The positive signals coming from the exhibition sector are an important step towards the normality confirming the value and relevance of face-to-face events.

The meeting in Vienna was also used to officially launch the new Eumabois website with completely renewed and modern graphics. There were also important news on the technical projects side.: OPCUA (Open Platform Communication Unified Architecture) got the marketing name “IZY”, which has been officially presented to the market during LIGNA.Innovation Network on September 27th, 2021.

At the end of the Assembly, the president Jürgen Köppel expressed his sincere thanks to the hosting association FMTI and to all the present national associations, stating: “…I firmly believe that one of the key pillars for the growth of our industry is our joint European approach.”

The next Eumabois General Assembly will be held on 22nd-23rd of September 2022 in the city of Krakow, Poland.

Source: Eumabois

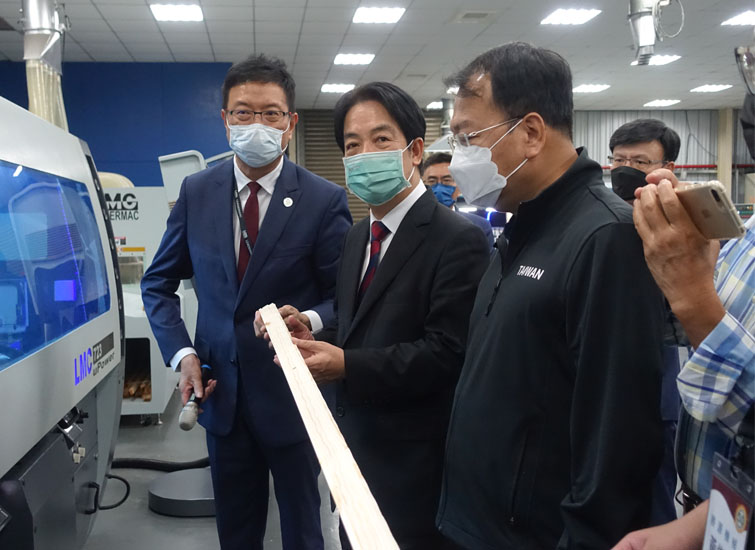

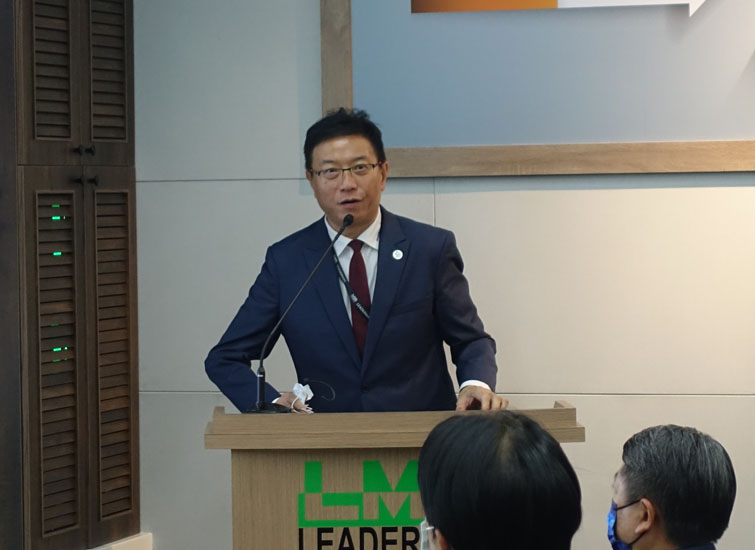

Leadermac 50th anniversary

- 2021-10-01

The time-honored "Leadermac" has been deeply involved in the woodworking machinery industry in Taiwan. Leadermac Machinery company now is the world’s second largest manufacturer of four side moulder. This year celebrates its 50th anniversary. The two generations relay of the Chang family in 50 years has completed the proud, "Taiwan number one. At this important moment, the editorial team interviewed Michael Chang, president of Leadermac, and listened to him elaborate on the company’s growth and future vision and plans.

.jpg) Leadermac important process monument

Established in 1972, Leadermac has gone through 50 years of testing, from the traditional woodworking machinery manufacturing to the largest professional manufacturer of four side planers in Taiwan and the second largest in the world. Chairman Michael Chang expressed its important turning point. In the successful decentralized market: Because the early market was too concentrated in the Asian and Southeast Asian markets, in order to enter the European and American markets, LEADERMAC brand was established in 1994, and the CE certification was simultaneously applied for, and at the same time, the mechanical and electrical specifications that comply with the European regulations were set up to European specifications to enter new markets. In 1995, Leadermac participated in the LIGNA Hannover Woodworking Machinery Exhibition in Germany for the first time. (LIGNA is the world’s largest international woodworking machinery exhibition held every two years), and successively find European agents, such as Denmark, Sweden, Finland and other countries. This is an important turning point for Leadermac to enter the European and American markets. With local agents in Europe, Leadermac successfully explored the European market.

In 2013, it started to move towards the goal of automation from a single machine to an automated .the year 2020, the automatic production equipment for the solid wood production line was released. It is an important process of the automation of Leadermac in recent years, and it is also an intelligent production. Set rules.

Leadermac important process monument

Established in 1972, Leadermac has gone through 50 years of testing, from the traditional woodworking machinery manufacturing to the largest professional manufacturer of four side planers in Taiwan and the second largest in the world. Chairman Michael Chang expressed its important turning point. In the successful decentralized market: Because the early market was too concentrated in the Asian and Southeast Asian markets, in order to enter the European and American markets, LEADERMAC brand was established in 1994, and the CE certification was simultaneously applied for, and at the same time, the mechanical and electrical specifications that comply with the European regulations were set up to European specifications to enter new markets. In 1995, Leadermac participated in the LIGNA Hannover Woodworking Machinery Exhibition in Germany for the first time. (LIGNA is the world’s largest international woodworking machinery exhibition held every two years), and successively find European agents, such as Denmark, Sweden, Finland and other countries. This is an important turning point for Leadermac to enter the European and American markets. With local agents in Europe, Leadermac successfully explored the European market.

In 2013, it started to move towards the goal of automation from a single machine to an automated .the year 2020, the automatic production equipment for the solid wood production line was released. It is an important process of the automation of Leadermac in recent years, and it is also an intelligent production. Set rules.

.jpg) Inheritance and succession

Michael returned to Taiwan from Canada in 1992 and joined Leadermac. He started from the grassroots level and experienced production, management and business departments. Until 1999, he served as the company's general manager and entered the company's core business. Michael is gratefully said: "The most important thing is to thank my father for his support, so that I can carry out drastically, both internally and externally, so that I have the power to change, Michael thanked his father for his support, allowing him to give full play to his strengths and contribute to the company.

Inheritance and succession

Michael returned to Taiwan from Canada in 1992 and joined Leadermac. He started from the grassroots level and experienced production, management and business departments. Until 1999, he served as the company's general manager and entered the company's core business. Michael is gratefully said: "The most important thing is to thank my father for his support, so that I can carry out drastically, both internally and externally, so that I have the power to change, Michael thanked his father for his support, allowing him to give full play to his strengths and contribute to the company.

.jpg) At that time, the company's product sales were 90% concentrated in China and Southeast Asia, but after experiencing the economic storm in Asia in 1997, the team realized the importance of diversifying risks, so it set the goal of diversifying the market to avoid putting eggs in the same basket

Regarding entering the European and American markets, Michael said that this is a long-term journey. It is necessary to continuously participate in European and American international exhibitions step by step. The preparation process is like participating in the Olympic Games. Exhibit equipment not only meets the requirements of European regulations, but also respects and avoids patent protection. The expansion of the European and American markets adopts the strategy of Country surrounds the city, such as selling from small countries in Southern and Western Europe, and finally Enter the core group, such as Germany, France, Austria and other countries.

At that time, the company's product sales were 90% concentrated in China and Southeast Asia, but after experiencing the economic storm in Asia in 1997, the team realized the importance of diversifying risks, so it set the goal of diversifying the market to avoid putting eggs in the same basket

Regarding entering the European and American markets, Michael said that this is a long-term journey. It is necessary to continuously participate in European and American international exhibitions step by step. The preparation process is like participating in the Olympic Games. Exhibit equipment not only meets the requirements of European regulations, but also respects and avoids patent protection. The expansion of the European and American markets adopts the strategy of Country surrounds the city, such as selling from small countries in Southern and Western Europe, and finally Enter the core group, such as Germany, France, Austria and other countries.

.jpg) Challenges facing Taiwan in the post-epidemic era

Refer to the impact of the new crown pneumonia COVID 19 on Taiwan’s woodworking machinery, Michael analyzed that because Taiwan’s control of the epidemic is better than other countries this time, the Sino-US trade war has surfaced at this time, and the semiconductor industry has stabilized its leading position. The popularity of Taiwan has jumped up. At this moment, the world is relatively repulsive of Chinese products, and many foreign orders have been transferred to Taiwan and other Asian countries. Take Leademac as an example. The biggest profit is the US market, plus tariff preferences, which is the best period in history

However, internal obstacles, including rising source materials, exchange rate fluctuations, soaring freight rates, and the shortage of AI talents in Taiwan’s manufacturing industry, have caused various difficulties in the internal operations of Taiwan’s manufacturing industry and have also tested the wisdom of leaders.

About Future

Regarding the future, Michael said that continuous positive thinking and continuous change are like the company's motto and vision: "The only constant in life is change, the pursuit of excellence and the goal of a happy company." To achieve a happy company, you must satisfied customers, because when the customer is satisfied, the company will have continuous orders, and gain profits for the R&D promotion of various departments of the company, especially in terms of AI and IOT overflow and employee benefits, so as to continue to promote the happy enterprise and the industry. 4.0 forward. However, compared with large foreign companies, Taiwan’s happy companies are not necessarily to be large. However, in the future, the weapon that determines the success or failure of the company is to invest in AI, otherwise the road ahead will be very hard. This is the way to go.

Photos by Leadermac

By NewsWin

Challenges facing Taiwan in the post-epidemic era

Refer to the impact of the new crown pneumonia COVID 19 on Taiwan’s woodworking machinery, Michael analyzed that because Taiwan’s control of the epidemic is better than other countries this time, the Sino-US trade war has surfaced at this time, and the semiconductor industry has stabilized its leading position. The popularity of Taiwan has jumped up. At this moment, the world is relatively repulsive of Chinese products, and many foreign orders have been transferred to Taiwan and other Asian countries. Take Leademac as an example. The biggest profit is the US market, plus tariff preferences, which is the best period in history

However, internal obstacles, including rising source materials, exchange rate fluctuations, soaring freight rates, and the shortage of AI talents in Taiwan’s manufacturing industry, have caused various difficulties in the internal operations of Taiwan’s manufacturing industry and have also tested the wisdom of leaders.

About Future

Regarding the future, Michael said that continuous positive thinking and continuous change are like the company's motto and vision: "The only constant in life is change, the pursuit of excellence and the goal of a happy company." To achieve a happy company, you must satisfied customers, because when the customer is satisfied, the company will have continuous orders, and gain profits for the R&D promotion of various departments of the company, especially in terms of AI and IOT overflow and employee benefits, so as to continue to promote the happy enterprise and the industry. 4.0 forward. However, compared with large foreign companies, Taiwan’s happy companies are not necessarily to be large. However, in the future, the weapon that determines the success or failure of the company is to invest in AI, otherwise the road ahead will be very hard. This is the way to go.

Photos by Leadermac

By NewsWin

“SUP DIRECTIVE” AND THE FUTURE OF PLASTICS

- 2021-07-24

Starting from the 3rd of July of this year, the European Directive “SUP” (Single Use Plastic) has come into force in all member states. A directive that does not apply in any way to furnishing products – a sector in which Catas, the most important European laboratory in the sector, has been involved for more than fifty years – but which can lead to some careful thoughts on the theme of plastics. The “banning” of some disposable items responsible for a large part of the pollution of our planet – including plates, cutlery, straws, etc. – is undoubtedly a strong signal of the explicit desire to tackle the issue of materials which are considered “not sustainable ". A directive that can and must therefore be interpreted as a first signal towards the limitation of the production and use of plastics in more general terms, considering the continuous and growing global alarms. Among these, one of the most dramatic concerns the accumulation of plastics and microplastics in the oceans which, continuing at current rates, will contain more plastic than fish already by 2050. Therefore the final goal could even bring to more drastic measures, as a recent article suggests. The prestigious journal “Science”, published an appeal signed by 14 scientits of various countries for an international agreement which goal would be the prohibition of the production of new virgin plastic already starting from 2040. From that date, therefore, only recycled plastic could be used. This situation and its probable, although not desirable, dramatic evolution therefore requires a careful consideration. Possible strategies should aim at the future concerning, in addition to ethical and environmental aspects, also the marketing strategies of the furniture sector or of the individual companies belonging to it. We must necessarily pay attention to the evolution of this general picture, starting also to consider the possible alternatives, bioplastics, their compostability, rather than coming back, where possible, to wood. Catas is particularly active on environmental issues and, precisely to meet the changing needs of an increasingly “green” market, it recently has developed a new service for the study of the life cycle assessment (LCA) of any raw material or finished product in the wood-furniture sector. We remind you that the Life Cycle Assessment provides a sort of environmental “identity card” based on international shared rules and unified principles. The LCA study is therefore the objective basis on which to work towards improvements, awards and certifications. Source:CATAS